CDO2

A problem-solving entrepreneur has won support from UK Research and Innovation’s Faraday Battery challenge for a novel image-sensing solution to the problem of monitoring electric-vehicle batteries for safety and performance.

Dr Gary Kendall in his laboratory

Dr Gary Kendall in his laboratory

When East Sussex businessman Dr Gary Kendall decided to exit the world of banking risk analysis in 2017, he never imagined that today he would be using quantum technology to develop diagnostic sensors for electric vehicle (EV) batteries.

With support from UK Research and Innovation through the Industrial Strategy Challenge Fund’s Faraday Battery Challenge, his company CDO2 has devised a new generation of sensors, able for the first time – using this method – to indicate if a battery is safe and fault-free.

Now CDO2 is about to play a key role in a £5.4 million collaborative project, also funded by UKRI, that pairs its non-invasive battery monitoring with quantum technology. This will allow for extremely sensitive measurements to be made of the magnetic field associated with current flow density within an EV battery.

The aim of the project is to incorporate a pre-production prototype into the UK’s largest commercial lithium-ion and sodium-ion battery manufacturing line at a plant owned by AMTE Power.

The collaborative project also involves the Centre For Process Innovation, the Compound Semiconductor Centre, Compound Semiconductor Technologies Global, Cosworth, Kelvin Nanotechnology, Magnetic Shields, Optocap, the University of Strathclyde and the University of Sussex.

CDO2 will receive around £600,000 towards its costs over three years, which will mainly cover the cost of four additional staff.

In offering a unique and low-cost window into a battery’s internal workings, CDO2’s innovation has generated much interest in the EV sector.

CDO2 will receive around £600,000 towards its costs over three years, which will mainly cover the cost of four additional staff.

The initial 12-month feasibility study, funded by the Faraday Battery Challenge for a total of more than £450,000, ended in summer 2019. It involved CDO2 and academics from the University of Sussex and Queen Mary University of London along with component manufacturer Inex Microtechnology.

The feasibility study has already demonstrated that CDO2’s sensing technique can indeed ‘see inside’ a battery, maintaining a check on its performance and safe operation by interpreting the pattern of surrounding electro-magnetic fields.

It was a chance meeting with academics from Queen Mary’s Electronic Engineering department at a Knowledge Transfer Network event – ‘Quantum Technology for Transport’ – that shed light on the difficulties in measuring EV battery health and performance.

A crucial element of Dr Kendall's innovation originates in research that has taken place at the University of Sussex into mapping brain activity and magnetic fields created by naturally occurring electrical currents. CDO2 has since filed a joint patent with the university.

Dr Kendall said: “That’s where the inspiration came from. The patterns of the magnetic fields outside the brain can help you understand what’s going on inside. For people who design and build batteries, it’s something they would really like to know, too.”

Dr Gary Kendall

Dr Gary Kendall

Cornish Lithium

With support from UK Research and Innovation’s Faraday Battery challenge, a project in Cornwall could be supplying a substantial amount of the UK’s future demand for lithium required for electric vehicle batteries.

Cornwall could be producing a third of the UK’s lithium requirement for electric vehicle (EV) batteries within five years, thanks to a venture supported by UK Research and Innovation (UKRI) through the Faraday Battery challenge.

Cornish Lithium Ltd was part of a £500,000 feasibility project, ‘Securing Domestic Lithium Supply Chain for UK’ (Li4UK), led by mining consultant Wardell Armstrong International and involving the Natural History Museum’s advanced lithium laboratories.

For EV batteries and energy storage alone, Europe will need up to 18 times more lithium by 2030. However, there is currently no commercial battery-grade lithium production in Europe, a fact reflected in the EU adding lithium to its ‘critical raw materials’ list in September 2020.

In one strand of the Li4UK project Cornish Lithium assessed the potential to produce lithium from geothermal waters across the UK and found that Cornwall has the highest potential for this. The company is targeting lithium production from lithium-enriched geothermal waters that circulate at high temperatures in fault lines deep within Cornwall’s granite geology.

Cornish Lithium intends to pump these waters so they surface via boreholes, and extract lithium from them using low-carbon direct lithium extraction technology such as adsorbent beads. The company is also hoping to utilise geothermal energy produced from the same waters to power the processing plant and produce negative carbon lithium. Once the lithium has been extracted, the water will be returned to the granite while spare power is shared with nearby businesses and communities, including a planned rum distillery.

Cornish Lithium team members walking through a quarry

Cornish Lithium team members walking through a quarry

Jeremy Wrathall, CEO and founder of Cornish Lithium, said: “Producing lithium from geothermal waters is particularly attractive because it is very low in environmental impact.”

The first of several pilot lithium extraction plants will employ 10 people at United Downs on an industrial site. Cornish Lithium is collaborating with the United Downs Deep Geothermal Power Project to produce lithium from its deep geothermal waters in the same area, through the company GeoCubed.

Wrathall added: “We are planning not just one pilot facility, but four. We believe a full-scale plant would generate 50 to 100 jobs.”

The company is also intending to extract and process lithium-laden mica deposits from old China clay pits just north of St Austell, an area with high unemployment.

Wrathall added: “The UK economy will need 75,000 tonnes of lithium carbonate by 2035. We believe we can supply as much as 20,000 tonnes from both geothermal waters and by extracting micas from the hard granite.”

Cornish Lithium was awarded £111,000 for Li4UK by UKRI via the Faraday Battery challenge and received an additional £10,000 continuity grant to cover COVID-19 disruption. The company has also won £4.84 million for the GeoCubed project from the UK government’s Getting Building Fund, with Cornwall LEP as a partner.

Wrathall said: “Support from UKRI’s Faraday Battery challenge to help us establish a low carbon, sustainable source of lithium in the UK from primary domestic sources has accelerated our route to commercial production and helped to leverage further funding – private and government – for Cornish Lithium.

“The Li4UK project has significantly raised our profile, both locally and nationally, and is helping to raise awareness of the need to invest in secure, transparent and domestic upstream supply chains for battery metals.”

A Cornish Lithium employee examines rock samples collected

A Cornish Lithium employee examines rock samples collected

“We are planning not just one pilot facility, but four. We believe a full-scale plant would generate 50 to 100 jobs.”

AMPLiFII-2

Supported by UK Research and Innovation via the Faraday Battery challenge, this project built a sustainable battery system supply chain across several sectors. electric-vehicle batteries for safety and performance.

Delta motorsport e4 coupe

Delta motorsport e4 coupe

Engineering consultancy Delta is accelerating the electrification of high-performance vehicles through the development of a scalable battery solution. Supported by UK Research and Innovation (UKRI) via the Faraday Battery Challenge, the engineering consultancy worked with several industry partners to scope out and fulfil their battery needs. The result is a battery module design that can be configured to meet virtually any customer requirements.

James Arkell, Head of Programmes at Delta, explained: “The partners gave us their different perspectives of what was needed and the result was a modular, scalable solution. We can scale the module size, shape and characteristics and use different cells. This means we can get customers up and running quickly, as we are 99% of the way towards what they want with a ‘bespoke-off-the-shelf’ solution.”

The AMPLiFII-2 project ran from 2018 to 2020 and was a follow-on from AMPLiFII (Automated Module to pack Pilot Line for Industrial Innovation), another two-year UKRI-funded project. This second project built on the successes of the previous one, with Delta as the lead partner. The focus was on improving the manufacture of battery packs for electric and hybrid vehicles and building a sustainable supply chain across the various sectors. It developed the functionality of the AMPLiFII battery system, enhanced charging and discharging rates, patented a module cooling system and reduced costs. It also incorporated a flex-circuit harness, improving pack-level integration.

The engineering consultancy took on a new facility to conduct the project work and secured an even larger manufacturing facility post-project. As a result of the AMPLiFII work, 15 new jobs were created and Delta was acquired by the automotive engineering company Cosworth, becoming the electrification arm of the business.

The project partners were the high-performance car manufacturer Ariel, Jaguar Land Rover, JCB, bus manufacturer Alexander Dennis, battery specialist Potenza, printed circuit technology specialist Trackwise and Warwick Manufacturing Group.

One of the key aims of AMPLiFII-2 was to build a stronger, broader supply chain of original equipment manufacturers (OEMs) representing different sectors. According to James, the project was successful in achieving that.

In enabling a relatively low-cost and fast route to battery system development, we have opened up opportunities to lots of other manufacturers wanting to break into the world of electrification. It doesn’t have to be a huge company or involve a huge amount of money – it really opens up the market.”

The battery architecture has wider uses than just the automotive sector. James expects there to be a surge in interest from the marine sector and the aviation and aerospace sectors. The more OEMs that are able to take advantage of the improved battery packs, the bigger the environmental impact.

I-CoBat

New ways of cooling batteries could encourage more of us to drive electric vehicles.

Electric vehicles (EVs) have made big strides in recent years, both in their design and in the charging stations that are available for them. So what’s stopping us all from going electric?

When asked, people most frequently raise concerns over the time it takes for EVs to charge. We all have an idea of how quickly our petrol cars take to fill up, and until EVs’ charging times get close to this, they will always be at a disadvantage.

Aiming to do something about this is the Immersion Cooled Battery (I-CoBat) project, which is supported through the Industrial Strategy Challenge Fund, as part of the Faraday Battery challenge.

A cell module test area © WMG

A cell module test area © WMG

Battery cooling has long been a stumbling block on the road to faster charging of EVs: fast charging can indeed reduce waiting times for EV drivers, but it makes batteries hotter than they get under normal driving conditions. Getting too hot could mean batteries ageing prematurely, or failing altogether.

I-CoBat has been testing the viability of new cooling techniques for EV batteries. The company leading the project, M&I Materials Ltd, had already developed an environmentally-friendly synthetic liquid called MIVOLT, which it knew had potential for efficiently cooling batteries through immersion (immersion cooling being a promising alternative to existing techniques, such as air cooling). The problem was the amount of liquid that this would take and the weight of that liquid.

During the I-CoBat project, M&I has teamed up with engineering consultancy Ricardo Ltd, which has designed an innovative module that sits on an EV battery like a jacket, and directs the coolant only to where it is needed, meaning that much less liquid is required.

A large part of I-CoBat has involved simulations and tests to see how well these methods perform. Tests carried out by project partner WMG at the University of Warwick have shown that the new immersion cooling techniques enable EVs to charge 43% quicker. Just as importantly, tests carried out at the University of Liverpool showed no unwanted reactions between the MIVOLT liquid and the internal chemistry of batteries.

For M&I, the I-CoBat project has already led to further collaborations with EV manufacturers, who are interested in making immersion cooling work with their own particular batteries. In January 2021, for example, it was announced that MIVOLT would be used by California-based mobility specialists Faraday Future, in the battery pack they have developed. Further projects are looking at possible applications in the aerospace sector.

M&I’s Technical Director, Mark Lashbrook, said: “As an SME, working with the support of the ISCF’s Faraday Battery challenge and being able to use the facilities and research know-how of our partners has meant that we could get much quicker to where we wanted to be. The opportunity to work with renowned companies like Ricardo and research partners such as WMG has really raised our profile, too.

With the positive results of I-CoBat, we’ve shown that there are no show-stoppers that would prevent these techniques from being used. With immersion cooling, we can get charging down to less than seven minutes for 200 miles in range: enough for you to plug in your EV, go and have a coffee, and have enough charge to be well on your way.”

LiNaMan

New kinds of batteries are helping with the move to sustainable energy.

Dr Richard Dawson, technical director, LiNa Energy

Dr Richard Dawson, technical director, LiNa Energy

From using more solar and wind power to electrifying transport, reducing our carbon emissions depends on having safe, compact, low-cost batteries to store energy. Currently, rechargeable lithium-ion batteries are the gold standard in battery technology, but an exciting alternative is on the horizon.

Sodium-nickel-chloride (Na/NiCl2) batteries are safer than the more common lithium-ion cells. They operate at a higher temperature, simplifying cooling systems in varying ambient conditions - a boon to engineers. Na/NiCl2 batteries require less complex balance of plant, they don’t use scarce materials (such as cobalt, which is expensive and difficult to source), and they’re mostly recyclable.

Na/NiCl2 batteries have been around since the 1980s, but the technical difficulties in making them affordable have not been overcome until now. By exploiting recent advances in nano-ceramic materials and laser manufacturing processes, LiNa Energy (a Lancaster University spin-out) has produced an innovative design of a Na/NiCl2 cell and stack that offers the prospect of mass manufacture at a price the market is bound to embrace.

“This has huge disruptive potential.”

Dr Richard Dawson, technical director, LiNa Energy

A 12-month feasibility study, supported by a grant of £198,712 through the Industrial Strategy Challenge Fund’s Faraday Battery Challenge, has demonstrated the new batteries’ viability. The LiNaMan project, a collaboration between LiNa Energy, Lancaster University and the Centre for Process Innovation, has applied modern material engineering and processing to Na/NiCl2 chemistry.

LiNa Energy’s technical director Richard Dawson said: “We knew that the fundamental chemistry of sodium batteries was safe and out of patent, which allowed us to update the design in a radical way to deliver greatly improved power and energy density.

“The original cells were big – as tall as a drinking glass, and if you held one, your fingers wouldn’t meet around it. But because of the nano-engineered materials we use, the new planar cells are much more compact and can be efficiently arranged in flexible pack designs to maximise mass and volume specific performance.”

The project demonstrated proof of concept by its completion in October 2019, but as Richard explained, “The aim wasn’t just to create a prototype that performs brilliantly in the lab, but one that can be manufactured at a reasonable price. The success of project LiNaMan gave confidence to our investors, who contributed £1.6 million at the end of 2019, several times more than our fundraising target.”

LiNaMan was also crucial in LiNa Energy obtaining funding for a £1 million project from the Department for Business, Energy and Industrial Strategy’s Energy Entrepreneurs Fund, to help bring the new batteries to market.

“Our head count has increased to 15 skilled staff and we are planning further skilled, technical recruitment,” said Richard. “We are aiming for mass manufacturing at low cost, which has huge disruptive potential. Our goal is to replace lithiumion batteries with something safer, cheaper and better for the environment in high-volume applications such as the automotive and energy-storage sectors.”

MAT2BAT

With support from UK Research and Innovation’s Faraday Battery challenge, Ansys and project partners have developed a tool and database to help users explore new battery module designs.

There is a global drive towards electrification. Core to achieving it is the design and development of greener, better batteries. However, battery cells, modules and packs are complex systems, leading to multiple challenges around interdependencies, materials and components.

In 2018, Granta Design (which in early 2019 became part of the engineering simulation and 3D design software company Ansys) joined forces with Imperial College, London and battery manufacturer Denchi Group to tackle these design issues. Funded by UK Research and Innovation via its Faraday Battery challenge, the year-long MAT2BAT project resulted in an early-stage practical battery module design tool and a database, both of which are fully integrated in the Ansys Granta commercial and education software packages.

What this means is that technical professionals working in industry, such as engineers and designers, can use the Ansys Granta Selector software to explore and compare multiple different design configurations, quickly and easily, in the early stages of design and development. Student engineers can learn about the key concepts of cell/module selection and design through Ansys Granta EduPack, the materials engineering software used by over 1,000 universities and colleges worldwide.

Alex Cazacu, Senior R&D Project Manager at Ansys, said it will help existing and future engineers learn about, explore, test and design battery innovations. “We are supporting engineers to design new, better cells and we are training new engineers in this area. A tool like this enables people to churn through a lot of combinations of cell configuration, and they can discover materials and specifications that they wouldn’t otherwise see.”

The tool and data set help users understand design components and performance metrics, enabling them to explore relationships between battery module design and performance.

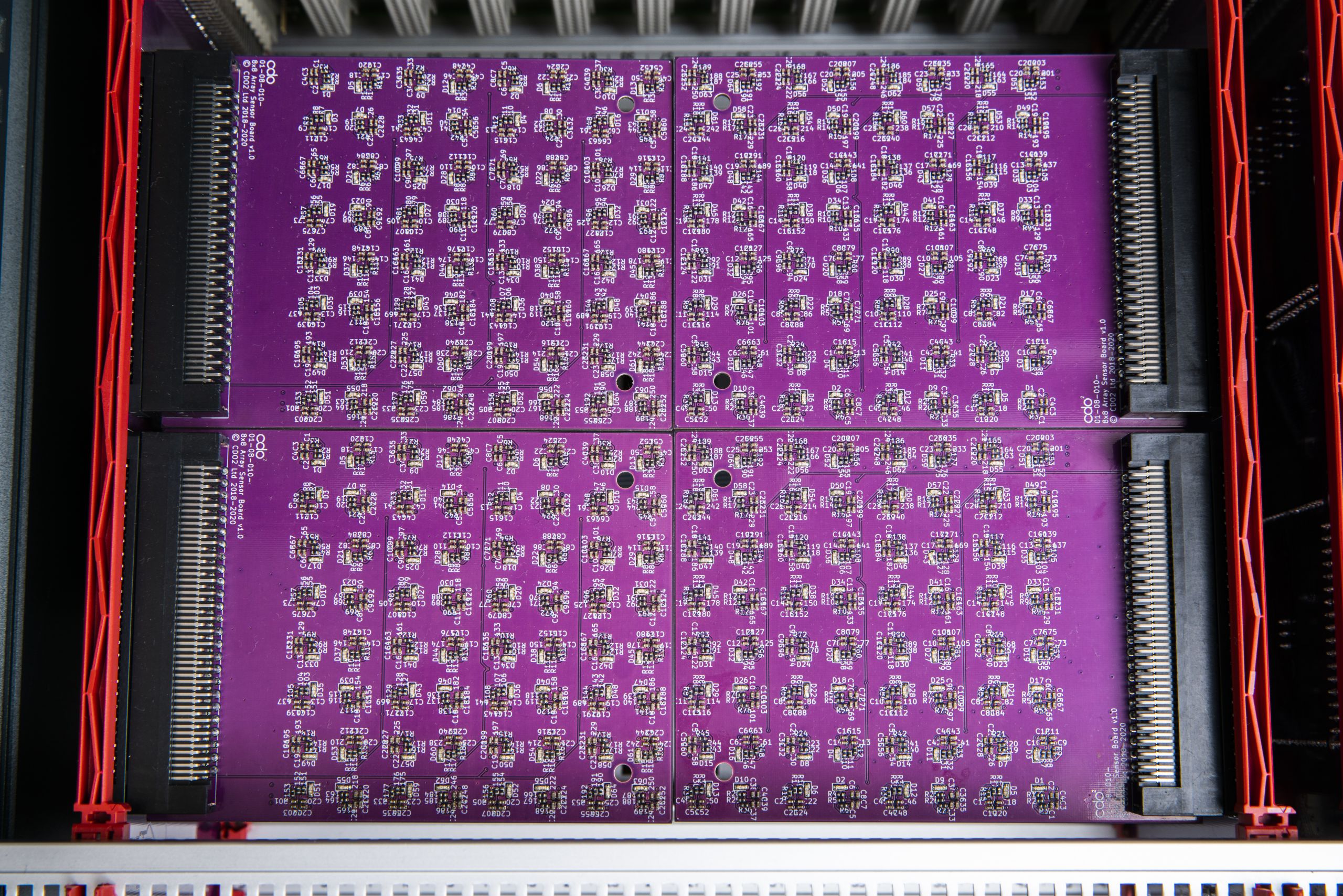

Connected battery modules forming a pack

Connected battery modules forming a pack

Roger Barnett, Senior Product Manager at Ansys, said using the tool and database in the preliminary design and development phase is beneficial to industry and to students, for several reasons.

Roger said: “Users can pick lots of different designs and explore them all at the same time, narrowing down the field of possible combinations. It is very easy and low cost to change things at the start of the design and development process. Towards the end of the process, there is much less flexibility for making changes and the costs are higher.”

MAT2BAT was a truly collaborative project, with Imperial College developing the design methodology, Ansys developing the software tool and database and Denchi Group helping with industrial models and user feedback. When the project ended in 2019, Ansys spent an additional year developing the tool and database and turning them into finished products.

Batteries are complex systems with many design challenges. This UKRI-funded project was key to tackling these challenges. Our users can rapidly explore new designs and optimise their products for an electrified future.”

Further information

Go to Battery Innovation Network (ukbatteriesnetwork.org) to join the growing battery community in the UK.

Visit Faraday battery challenge at UKRI for more information on the Challenge.