To create a low carbon economy, a business has developed compound semiconductor technology to enable smaller, lighter and more energy-efficient power systems.

SiC (silicon carbide) is a compound semiconductor composed of silicon and carbon. A silicon carbide power module transforms electrical power, which is the product of current and voltage with high conversion efficiency.

Growth in this area has historically come from adopting SiC diodes and metal–oxide–semiconductor field-effect transistors (MOSFETS) in renewable energy applications and greener, more efficient air conditioning systems.

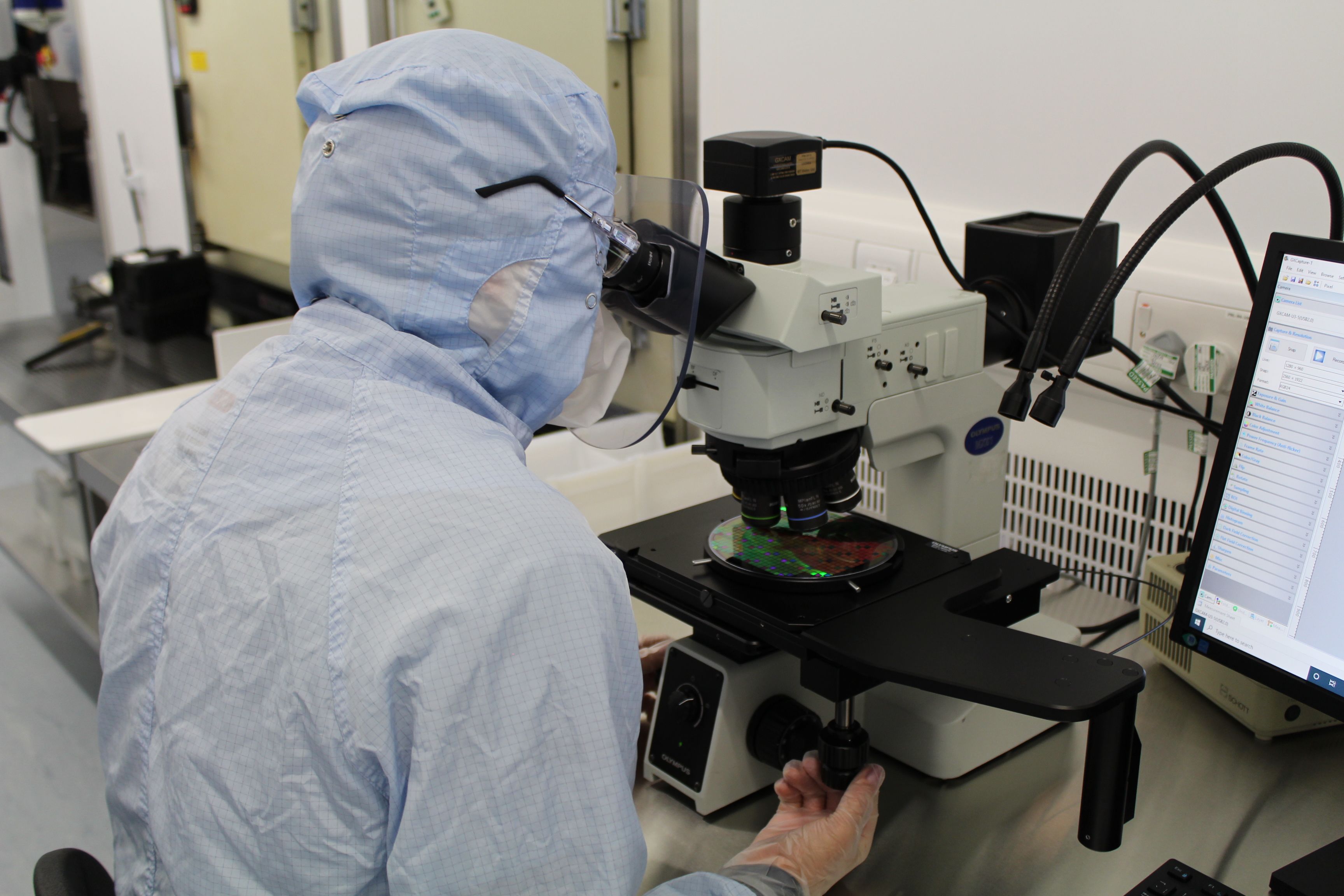

Credit: Clas-Sic Wafer Fab Ltd.

Credit: Clas-Sic Wafer Fab Ltd.

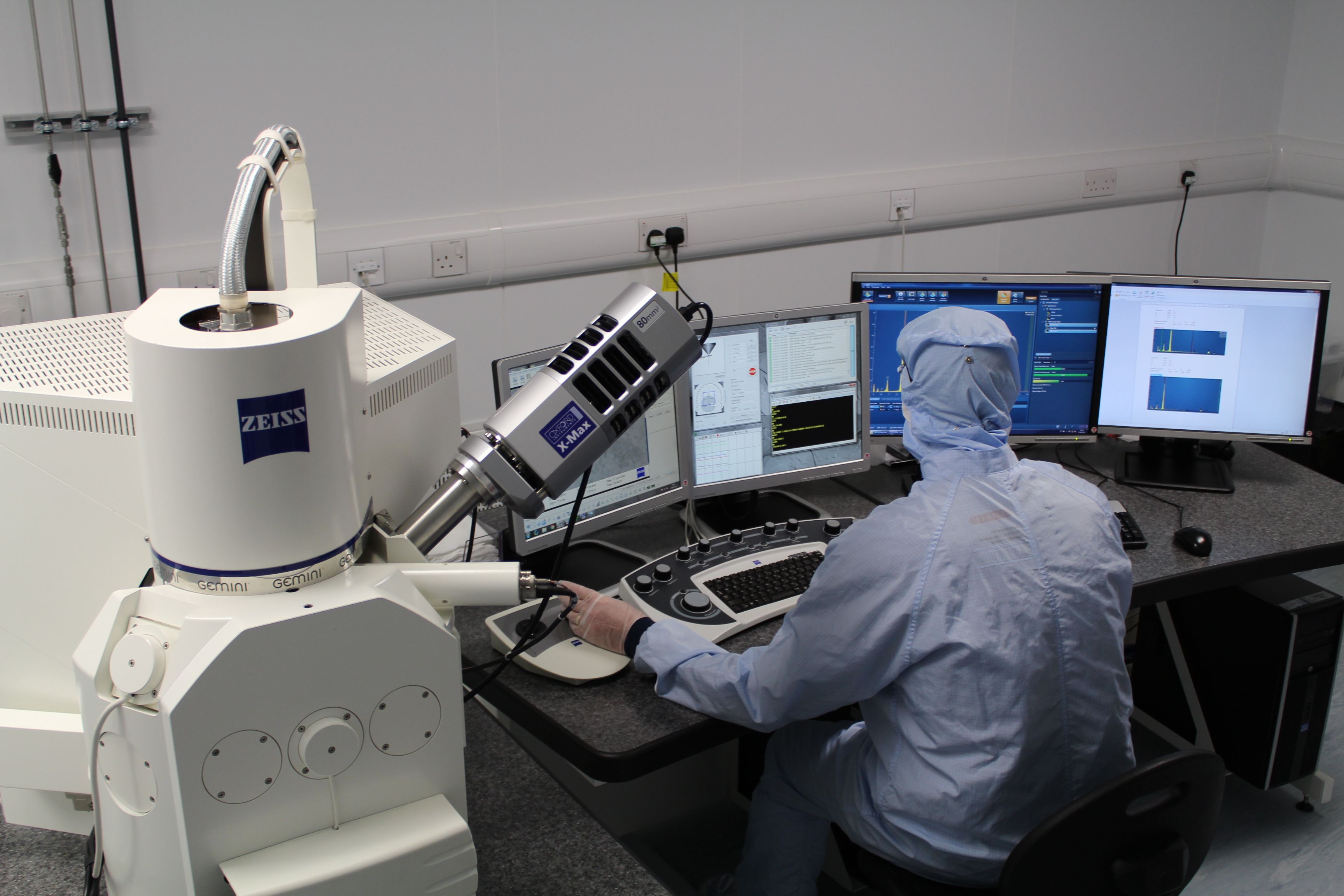

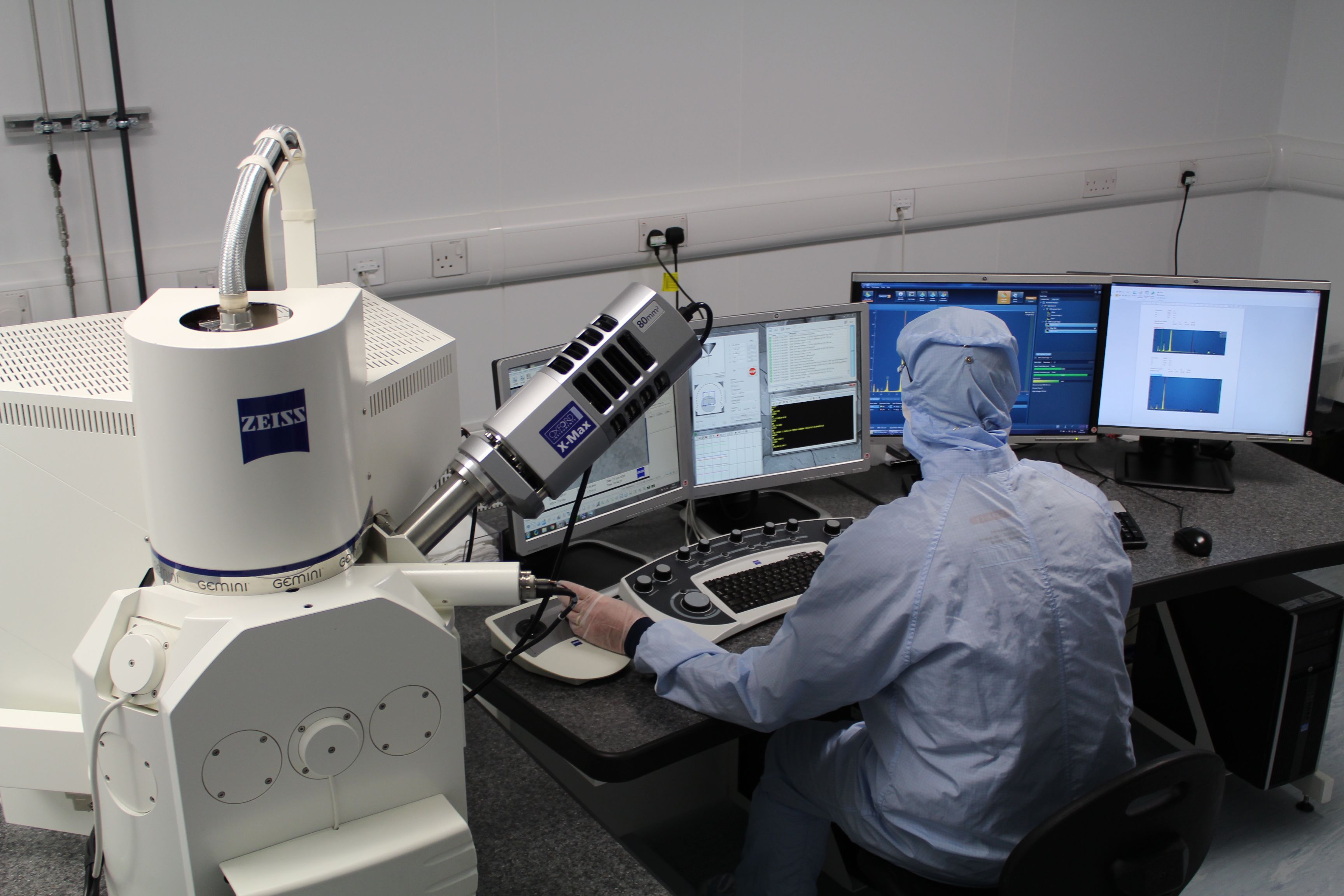

Credit: Clas-Sic Wafer Fab Ltd.

Credit: Clas-Sic Wafer Fab Ltd.

Clas-SiC Wafer Fab is the world’s first dedicated open 150mm pure-play foundry to manufacture silicon carbide power semiconductors. The company has developed low to medium-scale SiC production capacity to deliver a time-to-market advantage. It has taken a 1,200 volt (V) planar SiC MOSFET process and expanded it to include 1,700V and 3,300V capabilities.

Clas-SiC Wafer Fab’s Technology Manager, David Clark, said: “The innovation with our SiC technology is in our process design kit (PDK), which reduces risk and creates a faster time to market for new products.

Fife-based Clas-SiC Wafer Fab began in 2017 with $50 million in private investor funding. Clas-SiC has now entered the volume manufacturing phase and is experiencing steep growth in customer demand, mainly driven by the international drive towards net zero and the electrification of transport.

“The PDK enables customers to have 1,200V SiC MOSFET devices tailored to their specific requirements using established design elements, modules and processes that have proven essential reliability.”

David Clark said: “We can now create energy efficiency and savings through serving the higher voltage markets by providing 1,700V and 1,200V PDKs.

“By distributing energy at a higher voltage, we’re using less current, so you incur less conduction losses, meaning greater efficiency, longer ranges for battery electric vehicles thus advancing efficient electrification.”

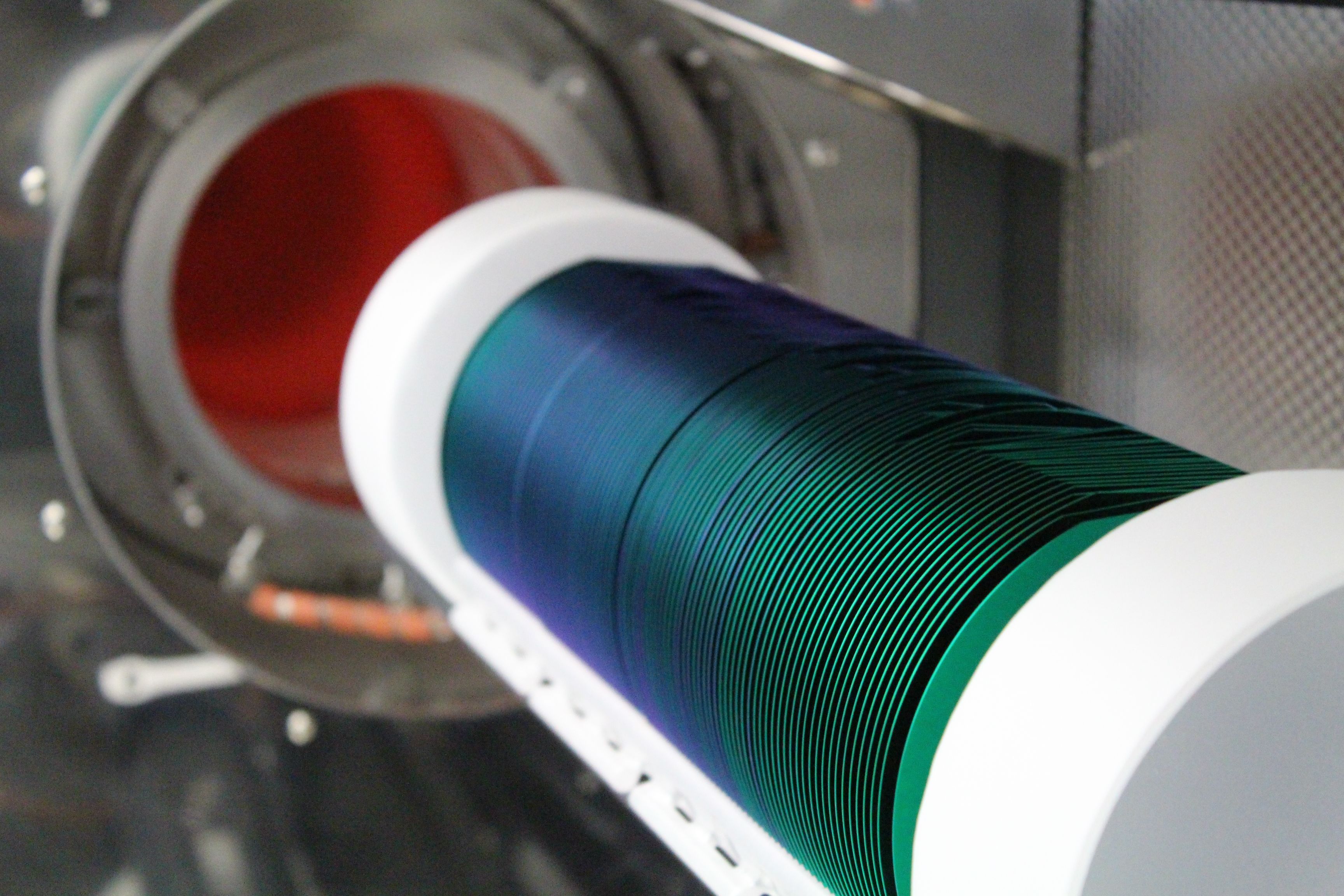

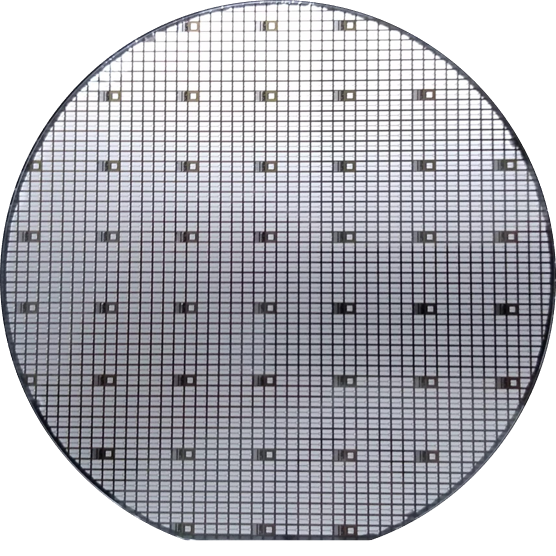

Credit: Clas-Sic Wafer Fab Ltd.

Credit: Clas-Sic Wafer Fab Ltd.

In 2020, Clas-SiC Water Fab won an Innovate UK grant of £282,993 through the Driving the Electric Revolution Challenge, part of the UK Research and Innovation (UKRI) Challenge Fund at UKRI. Over 20 innovative projects aiming to reduce carbon emissions in the transport, energy and industrial sectors shared nearly £6 million in funding.

Clas-SiC Water Fab is now developing next-generation energy solutions, selling power silicon carbide devices into the international market, resulting in increased media publicity, UK exports and a real contribution to the green economy and job market.

Clas-SiC Wafer Fab’s Managing Director, Rae Hyndman, said: “Through a new partnership, we are in the process of supplying MOSFET’s to a custom design.

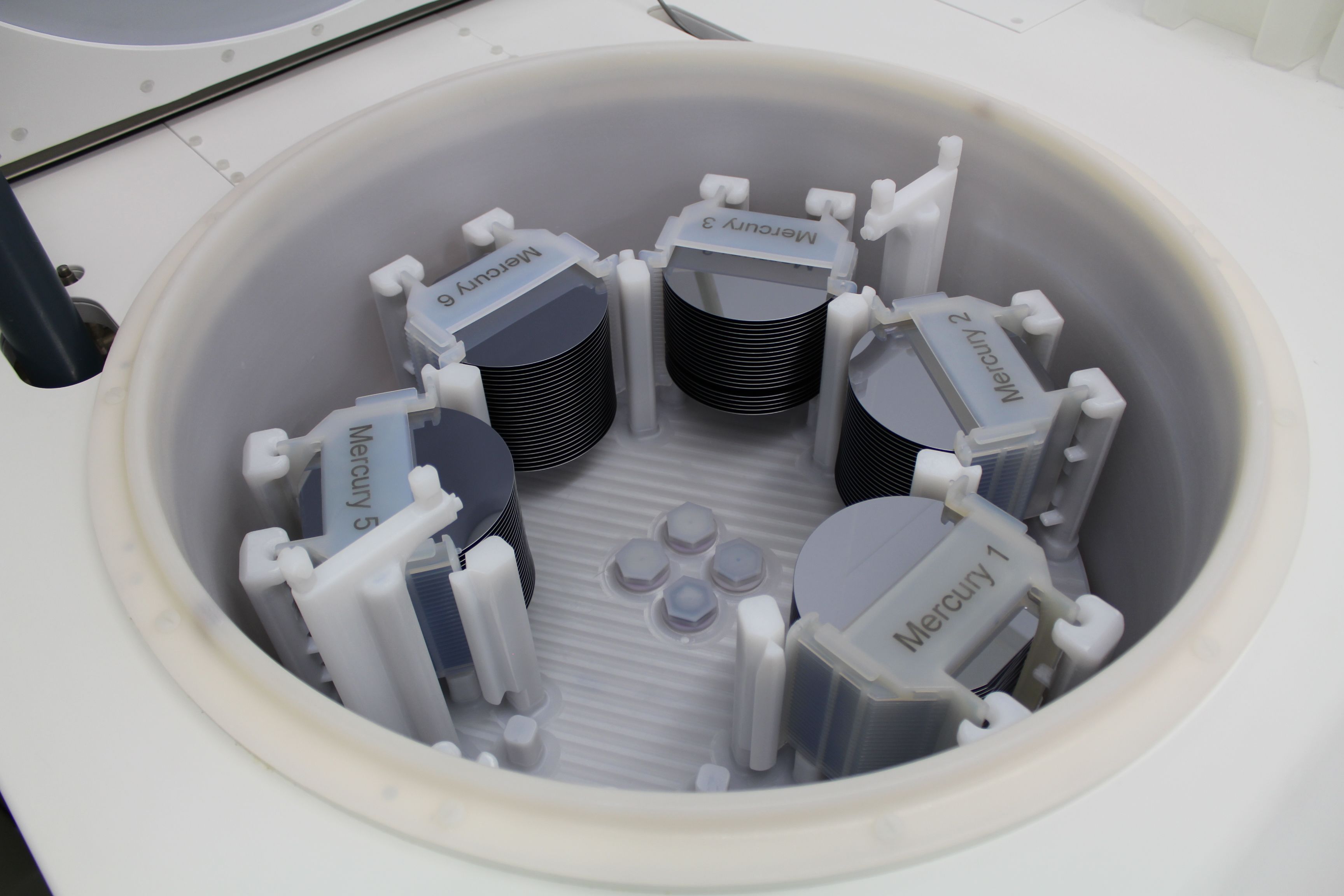

Credit: Clas-Sic Wafer Fab Ltd.

Credit: Clas-Sic Wafer Fab Ltd.

Credit: Clas-Sic Wafer Fab Ltd.

Credit: Clas-Sic Wafer Fab Ltd.

“From this, we want to help transform the grid to achieve higher efficiencies and to accommodate smart and bidirectional charging where vehicles supply the grid.

“We’ve made many vital contacts, collaborations and spin-off projects due to our UKRI funding and support.

“We are working on advanced, ultra-rapid battery charging and participating in the development of an end-to-end supply chain for the UK. There is currently no end-to-end supply chain in the UK for advanced SiC baseds power electronics, and we want to change that to positively impact the industry.”