Executive summary

The UK Catalysis Hub, which has been supported by EPSRC since 2013, has built a thriving community of catalysis researchers in academia and industry. The Hub provides an important national capability, supporting a key UK industry sector. Research outputs from the Hub are leading to new, sustainable chemicals and manufacturing processes that will be vital if we are to tackle the climate crisis and minimise the environmental impact of the chemical and manufacturing industries globally.

Source: https://ukcatalysishub.co.uk/uk-catalysis-hub-achievements/

Secret ingredients

Most of us never think about catalysts, but they are the secret key to almost everything we make. Around 80% of manufactured products, including everyday items like fuels, fertilisers, much of our food and drink, cars, mobile phones, medicines and more, all rely on catalysts in their production.

Catalysts speed up chemicals reactions. They reduce the temperature and pressure required to manufacture new chemicals, reduce toxic by-products, and eliminate waste. They can help tackle some of the most pressing challenges facing humanity today – from the climate crisis to plastic pollution. Society needs new, faster, cheaper catalysts to create new medicines, unlock bio-based fuels, clean up our environment and reduce our dependence on unsustainable fossil fuel-based plastics.

x

[1] Source: Chemical industry in the UK - statistics & facts | Statista

[2] Source: https://www.cia.org.uk/about/what-we-do/economics-and-business-surveys

[3]The UK ranks second in the world according to field weighted citation impact of research publications in chemistry. Source: EPSRC internal analysis using data from Elsevier/SciVal.

They also support a major UK industry sector: chemicals and pharmaceuticals manufacturing. In 2021, this sector alone had a GVA of £30.7billion[1] and in 2023 directly employed around 151,000 people primarily focused in the North West, as well as Scotland, the North East and the Yorkshire/Humber region[2]. Supporting that industry is a robust chemistry research base[3], including groups investigating all sorts of different catalysts. UK catalysis research has a long history of success. For instance, 1960s research by ICI resulted in a copper/zinc oxide/alumina catalyst that reduced the cost and raw materials required for manufacturing methanol, and which was commercialised globally, leading the world in understanding and improving the catalysts we rely on. However, in the late 2000’s catalysis researchers realised there was more they could do.

Researchers led by Professor Sir Richard Catlow and Professor Graham Hutchings approached EPSRC with the idea of establishing a national catalysis hub to bring together catalysis researchers from different universities and disciplines. The new Hub would be based not at a university but at the Research Complex at Harwell, home to STFC-funded facilities like the Diamond Light Source, ISIS Neutron and Muon source and the Central Laser Facility. Access to these unique facilities was a vital element in the Hubs’ plans, and “Harwell is the only place in the world where researchers can access photon, neutron and muon based spectroscopic techniques in one location.” Hutchings added.

New approaches to catalysis research

Bringing the UK catalysis community together has opened up a number of new approaches for research. For instance, the Hub is enabling researchers to combine computational approaches with experimental studies, to give a more thorough understanding of their structure at an atomic level. Researchers at the Hub have used this combined approach, harnessing the Diamond Light Source, to understand one of the major reactions that takes place to remove ammonia from the exhausts of diesel engines, helping to tackle air pollution.

Researchers also used the ISIS Neutron and Muon Source to investigate the catalysts needed to produce fuels from simple molecules such as methanol. By harnessing methanol from sustainable sources, the researchers hope to reduce our reliance on unsustainable fossil fuels[4].

[4] See also: Methanol to hydrocarbons for net zero – UKRI.

Community building

The Hub team’s bid for funding was successful and the UK Catalysis Hub was established in 2013[5]. As well as core questions in catalysis research and design, the Hub had a strong focus on environmental sustainability and developing catalysts to enable society to switch to green manufacturing and green energy production. In 2015 the Catalysis Hub expanded to include biocatalysis research, which was formally incorporated into the Hubs research aims when they received a second round of EPSRC funding in 2018[6].

In this new phase, the Hub sought to build on the open, collaborative approach it had established earlier, with a renewed focus on the role of catalysis in water, energy and the circular economy.

[5] GtR (ukri.org)

[6] GtR (ukri.org)

Reducing reliance on unsustainable plastics

Catalysts may hold the key to reducing our reliance on plastics from fossil fuel sources and reducing our carbon footprint. Professor Matthew Davidson and Professor Chris Chuck from the University of Bath have developed catalysts to convert starch or sugar from plant-based sources such as sugar cane into a type of plastic called PLA. PLA is often used as a substitute for non-renewable PET plastics in food packaging and plastic films.

The catalysts operate under industrial conditions and avoid using environmentally-harmful heavy metals. The researchers worked with industrial partner Total Corbion PLA to commercialise the process, including development of industrial-scale. The new process will reduce carbon emissions from PLA production by 75% compared to most traditional plastics.

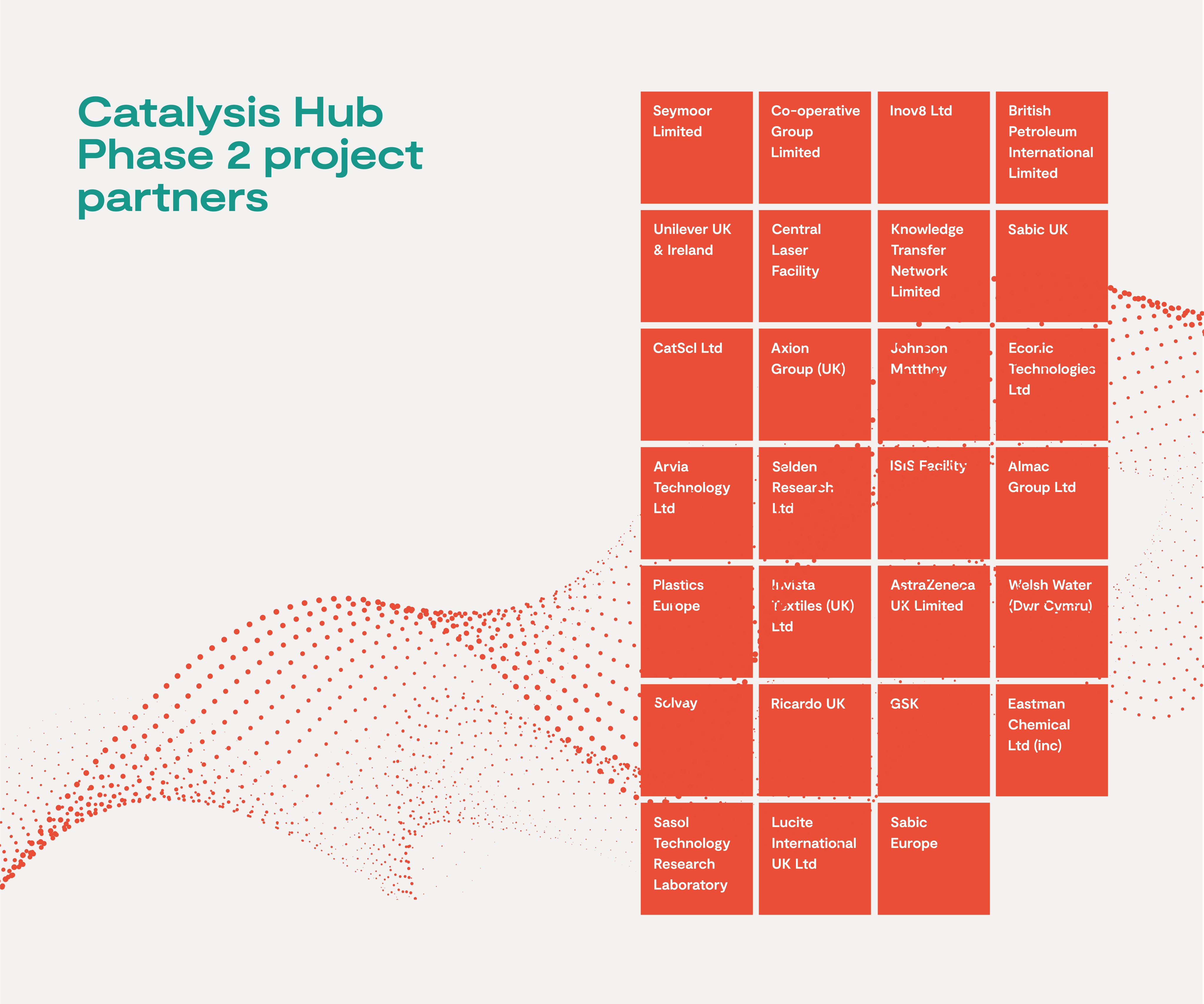

By 2018 the hub included more than 40 university research groups in collaborative research, as well as industry partners on many projects, and was a regular user of the Diamond Light Source and other facilities. Through its location at Harwell, the Hub was also able to champion the use of powerful neutron techniques for catalysis, driving the uptake of specific approaches and encouraging industrial partners to invest. For instance, industrial partner Johnson Matthey are now regular users of the laser, synchrotron and Neutron facilities and have supported studentships and researchers in this area.

From the start the Hub has brought together different institutions and actively sought out collaborations with major global companies and SMEs. Many of the Hub’s projects have received direct private sector investment as well as in-kind contributions including access to equipment, techniques and samples that would not otherwise be available.

As a result, companies working with Hub researchers have benefitted from a supply of highly skilled people – several have recruited former PhD students from the Hub – as well as new catalysts and process designs.

Hub scientists have also built strong international collaborations with researchers in South Africa, the USA and elsewhere. This has enabled more African researchers to access the beamlines at Diamond and ISIS. Working with researchers from the USA, the Hub researchers are focusing on fundamental research into catalysts needed for a circular carbon economy.

This collaborative, international outlook has led to major international impact, affecting global industry and influencing international policy and regulations.

From catalysis to the stars

Hub researchers, Dr Yagya Regmi and Dr Laurie King at Manchester Metropolitan University (MMU) are working with small company AVS UK to develop new catalysts for the space industry. AVS UK is building small satellites powered by hydrogen fuels cells. Palladium and Iridium catalysts, such as those being developed by the team at MMU are perfect for such fuel cells as they can be used both to produce hydrogen and oxygen and to generate power from hydrogen and oxygen when switched to fuel cell mode. Such technology would allow more sustainable energy generation that does not rely on toxic chemicals such as hydrazine, which is currently widely used in spacecraft propulsion.

The gold standard in plastics catalysis

What do the roofs of sports stadiums, artificial skin used in emergency burns care, and vehicle mud flaps all have in common? They’re all made from a type of plastic called PVC. Most PVC is made in China and, until recently, the manufacturing process relied on toxic mercury-based catalysts. However, working with industry collaborator Johnson Matthey, Professor Graham Hutchings at Cardiff University developed a new gold-based catalyst for use in PVC production. Recognising the value of the new catalyst, Johnson Matthey bought sole production rights to the mercury-free catalyst 2014. The company has begun industrial-scale manufacturing of the catalyst and it is gradually replacing the old mercury catalyst in the PVC industry in China.

Throughout, the Hub has provided training and skills development for catalysis researchers. Many of the postdoctoral research associates employed by the Hub have continued their careers in academic or industrial research positions. The Hub also offers training on specific techniques for UK-based and international researchers, as well as on broader topics such as commercialising research outputs, and provides networking and conferencing opportunities for early-career researchers.

Career focus

I feel very lucky to have been based at the Catalysis Hub - with its resources, outstanding expertise and position as a physical base for the numerous research institutions within the Hub network.

All of these made a huge difference to the quality of research I’ve been able to carry out, and my chances of becoming a future leader in studying the materials and chemical phenomena that fascinate me the most. I look forward to keeping a very strong, close relationship with the Catalysis Hub throughout my career, for all it has done for me and for the opportunities it brings.

Dr Alex O'Malley. PhD

with the Catalysis Hub in 2013, now a Lecturer in Chemistry at the University of Bath.

Our green future

EPSRC has awarded the Hub a third stage of funding from 2024. The demand for new catalysts is increasing, driven by the global climate crisis and the need to eliminate waste and pollution from manufacturing and other industries. New catalysts will make our manufacturing industries more sustainable, reduce CO2 emissions from the global chemical industry, and underpin renewable energy generation. Renewable sources of raw materials to reduce our dependence on chemicals from fossil sources will also require innovative new catalysts.

The Hub now forms a vibrant multidisciplinary community providing an important national capability for the UK. From 2024 the Hub’s core programme will focus on new technologies and methods, training and skills, and continuing to pull the catalysis community together. This will support three key priority areas for catalysis research in future: net zero, taking advantage of evolving digital technologies, and sustainable manufacturing.

Catalysis research in the UK continues from strength to strength and it is a reflection of its quality and impact that we have the opportunity for the UK Catalysis Hub III. One of the key aspects of the next phase of the Hub will be our engagement across the academic, industrial and international community to help deliver the essential catalysis research for Net Zero and Sustainability. It is great to see new and existing Hub researchers helping shape our research vision and we look forward to working together as a community in the future.

Professor Charlotte Williams

Director, UK Catalysis Hub 2024

Researcher focus: Dr Sarah Lovelock

Researchers such as Dr Sarah Lovelock, who won the Sir John Meurig Thomas Catalysis Medal at the UK Catalysis Hub Winter Conference in December 2023, will play a key role in delivering the Hubs’ future priorities[7]. Lovelock’s research focuses on sustainable production of molecules and materials that are of use to the pharmaceuticals industry, using biocatalysts. For instance, her group are developing new biocatalysts to produce RNA therapeutics, a new and rapidly developing type of medication. Their new platform allows manufacturers to produce their target molecules in a single process, rather than a series of steps, and minimises waste.

[7] Source: https://ukcatalysishub.co.uk/winner-of-the-sir-john-meurig-thomas-catalysis-medal-2023-announced/#:~:text=The%20UK%20Catalysis%20Hub%20have,18th%20of%20December%202023.

Renewables harnessed with biocatalysts

Researchers led by Professor Nigel Scrutton at The University of Manchester are using biocatalysis to produce a range of biodegradable compounds that can be used in pharmaceuticals, fragrances and in biofuel. The research combined computational and experimental studies to develop methods to produce the chemical building blocks from renewable substrates.

Useful products from waste carbon dioxide

Charlotte Williams. Professor of inorganic chemistry at the University of Oxford, is at the forefront of efforts to turn carbon dioxide (CO2) into useful products. In 2011 Professor Williams founded Econic Technologies to commercialise her work in the creation of catalysts that allow waste CO2, such as from power stations, to be transformed into polymers for use in areas as diverse as electronics, clothing, aerospace and healthcare.

Econic Technologies hopes that by 2030 30% of all polyol production will take place using its catalyst technology, which could save 3.5 million tonnes of CO2 emissions each year – the equivalent to taking two million cars off the road. In 2024 Econic signed an MoU with Sanyo Chemical to assess Econic’s technology for producing sustainable, high performance plastics.

Find out more