Remote monitoring of concrete condition (REMOCC)

Technology specialists and a university are working together to interrogate the safety and integrity of concrete structures, using steel fibres within the material as remote sensors.

Remote monitoring of concrete condition (REMOCC)

Technology specialists and a university are working together to interrogate the safety and integrity of concrete structures, using steel fibres within the material as remote sensors.

The widespread use of concrete across the construction sector means innovations in its use are valuable for cost, safety and environmental benefits.

When it comes to the impact of potential damage and the need to rebuild, having the ability to assess the level of concrete failure more accurately could result in substantial savings in each of these areas. Whether it’s bridges and road barriers struck by vehicles, buildings facing damage from earthquakes and other natural causes, or offshore wind turbine bases, there are many areas where assessing concrete structure safety is essential.

Lateral Logic Ltd, alongside project partners Fibre Technology and Sonemat, with the support of the University of Warwick and backed by the Transforming Foundation Industries (TFI) challenge, designed a project concept that focuses on utilising the increasing use of steel fibres to strengthen cast and uncast concrete. The project looks at the potential for using these fibres as a passive sensor to assess damage.

“With the growth of steel fibre reinforced concrete as a replacement for rebar construction, because of the lifetime performance benefits it provides, this gave a great opportunity to harness the fibres for our purposes,” says Robin Young, Director of Lateral Logic Ltd. “Using electromagnetic sensing, the fibres can become a valuable indicator of the impact of reversible and irreversible damage – thus potentially saving the need to rebuild and replace – as well as calculating load and stress information.”

The project aimed to develop sensor technology further to allow for more accurate readings and the ability to test and assess larger structures than is currently possible. “This would also allow for leaner concrete structures to be built,” adds Young, “If sensors can successfully prove the concrete’s ability to absorb common impacts, the optimum size can be found that still provides the necessary structural integrity – whilst reducing the carbon and cost impact of making unnecessarily large concrete structures. It also means concrete can be more commonly repaired than replaced.”

“A more effective use of sensor technology can make concrete production and use more efficient and effective, saving environmental and cost benefits, while improving critical structural integrity.”

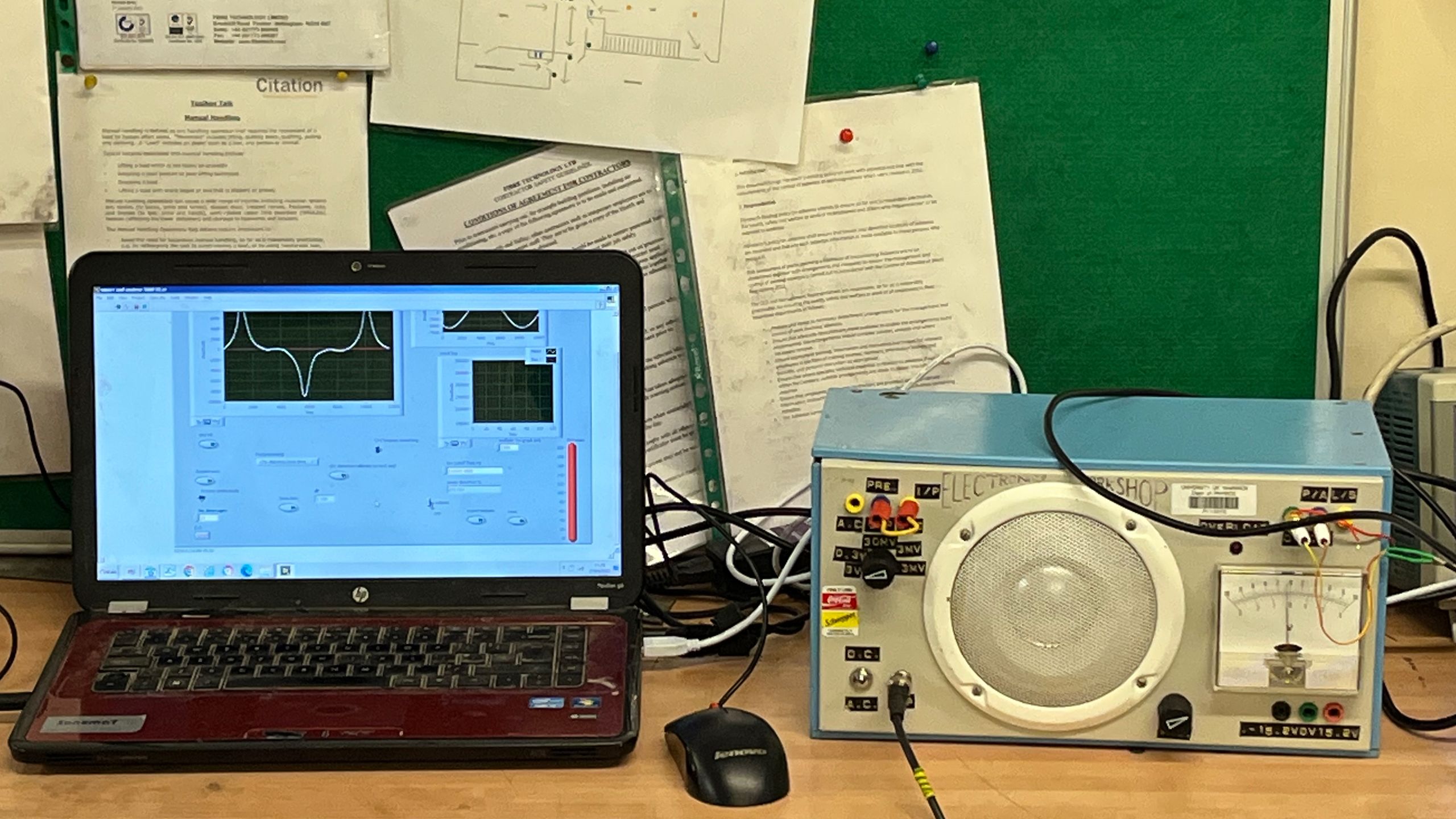

When it came to the results, the project made concrete samples with well-distributed steel fibres, which were then tested using an industrial press to put a load through the sample. A more advanced probe developed as part of the project was then used to assess impact.

Young comments: “The project’s goal was to prove the viability of moving the whole fibre sensor concept forward and to demonstrate the effectiveness of the technology, as well as showcasing the resulting downstream benefits that can be gained from the data produced in terms of production, monitoring and repair.”

“The proof of concept now allows us to pursue an increase in scale for assessment to larger structures,” Young adds. “We now have a portable prototype that will help us more widely demonstrate the technology to potential investors and the construction industry. This will help discussions around testing on larger structures than our samples and hopefully influence the better distribution fibres in production methods to improve the quality of results achieved by the technology.

The project partners will now pursue further funding to build larger structures and demonstrate the techniques for effectively using the tool, with the aim of supporting the more widespread use of fibres in concrete construction to coincide with the benefits of the sensor tool.

When it came to the results, the project made concrete samples with well-distributed steel fibres, which were then tested using an industrial press to put a load through the sample. A more advanced probe developed as part of the project was then used to assess impact.

Young comments: “The project’s goal was to prove the viability of moving the whole fibre sensor concept forward and to demonstrate the effectiveness of the technology, as well as showcasing the resulting downstream benefits that can be gained from the data produced in terms of production, monitoring and repair.”

“The proof of concept now allows us to pursue an increase in scale for assessment to larger structures,” Young adds. “We now have a portable prototype that will help us more widely demonstrate the technology to potential investors and the construction industry. This will help discussions around testing on larger structures than our samples and hopefully influence the better distribution fibres in production methods to improve the quality of results achieved by the technology.

The project partners will now pursue further funding to build larger structures and demonstrate the techniques for effectively using the tool, with the aim of supporting the more widespread use of fibres in concrete construction to coincide with the benefits of the sensor tool.