Algreen

The first environmentally sustainable and formaldehyde-free chipboard made from recycled waste paper and seaweed-based adhesive for furniture applications

Algreen

The first environmentally sustainable and formaldehyde-free chipboard made from recycled waste paper and seaweed-based adhesive for furniture applications

Biotech company have developed a new sustainable alternative to commercial chipboard for household furniture, using a combination of waste paper and seaweed. This product also removes the need to use formaldehyde as an adhesive. It supports broader environmental aims around paper recycling, reducing water use for production, and the sustainable benefits of aquaculture use.

Commercial chipboards use the petrochemical formaldehyde to glue woodchips together to make indoor and outdoor furniture, such as desks, beds, wardrobes and kitchen cabinets. These products can emit carcinogenic formaldehyde gas for up to 10 years, which can significantly reduce in-home air quality and increase chemical sensitivities and asthma – particularly in children.

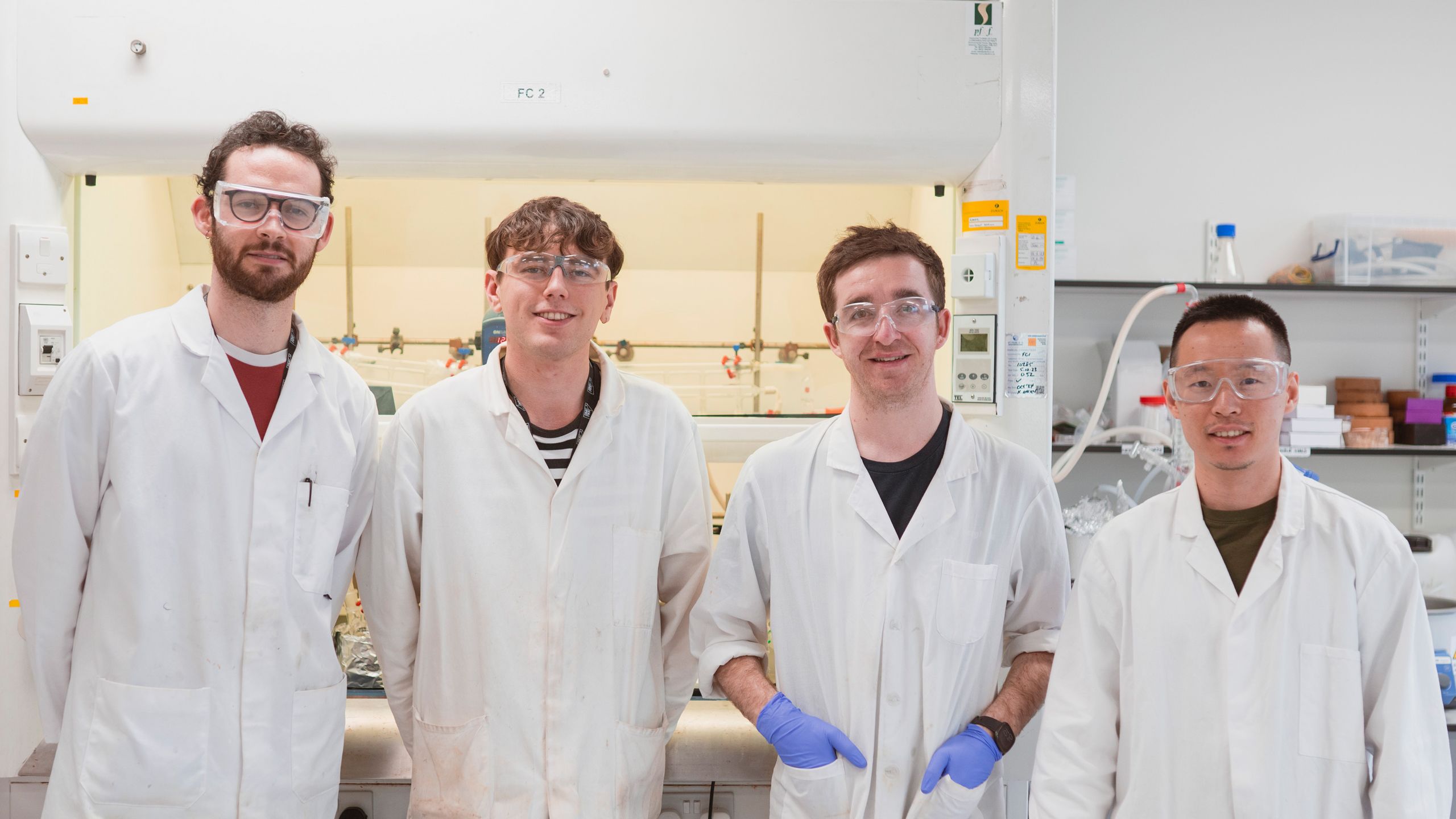

Algreen Ltd, with funding from the Transforming Foundation Industries (TFI) challenge, has developed a natural alternative material made from seaweed and recycled waste paper that matches the strength and performance of traditional chipboard but has a host of environmental advantages.

“It was imperative to find more ways to make furniture construction a lot greener,” says Zhixuan Wang, Founder of Algreen. “Seaweed is one of the most versatile and useful products, offering an alternative and sustainable adhesive component to this new approach to furniture – while also bringing wider ecological and economic benefits to its uptake across different industries. In our case, it was essential for helping tackle the concerning side effects of formaldehyde-based chipboard in people’s homes.”

The project aimed to demonstrate that using waste paper for all degradation would bring further sustainability benefits and that the product would be a genuine alternative to existing furniture in terms of quality, durability, and price. “When recycled directly back into the paper industry, waste paper can only realistically be re-used around seven times before the fibres become too degraded. The Algreen chipboard product uses waste paper of all standards, thereby extending its lifecycle greatly,” adds Wang. “We’ve also gone a further step by considering the use of waste hemp fibres for alternative products that help solve another source of waste – and that can eventually replace the need for paper.”

“The solution offers a new sustainable alternative to create greener furniture while also tackling paper recycling limitations.”

As a result, the project undertook various testing exercises of different material combinations against existing commercial formaldehyde-bonded chipboards. A lifecycle analysis of carbon use from raw material to end-of-life and assessments of operational costs and optimal production methods were also completed.

Wang comments: “Showcasing the benefits of using recycled paper was not difficult, given it offers substantial energy and water savings when compared to new paper and wood products. The ease of seaweed production following initial planting and its carbon-negative status also allowed us to progress with a sustainable and greener approach.

“From our analysis, using waste hemp fibres, which account for around 80% of the total hemp mass and are currently going to waste after other parts of the plant have been removed, actually have the potential to improve the furniture performance further,” Wang adds. “With a substantial existing feedstock from various countries, greater carbon capture benefits within the plant, and the potential for wider use, hemp offers a further solution in our efforts to replace existing carcinogenic furniture in homes.”

Algreen has since begun to develop its wider network, including demonstrations at international trade shows and conferences – both for the furniture sector and mechanical industries. Algreen have also been nominated for The Earthshot Prize 2024. The next steps are to scale up simulations to prove concepts further and refine materials before production is considered. The project will seek further funding and pursue patents for the products themselves.

As a result, the project undertook various testing exercises of different material combinations against existing commercial formaldehyde-bonded chipboards. A lifecycle analysis of carbon use from raw material to end-of-life and assessments of operational costs and optimal production methods were also completed.

Wang comments: “Showcasing the benefits of using recycled paper was not difficult, given it offers substantial energy and water savings when compared to new paper and wood products. The ease of seaweed production following initial planting and its carbon-negative status also allowed us to progress with a sustainable and greener approach.

“From our analysis, using waste hemp fibres, which account for around 80% of the total hemp mass and are currently going to waste after other parts of the plant have been removed, actually have the potential to improve the furniture performance further,” Wang adds. “With a substantial existing feedstock from various countries, greater carbon capture benefits within the plant, and the potential for wider use, hemp offers a further solution in our efforts to replace existing carcinogenic furniture in homes.”

Algreen has since begun to develop its wider network, including demonstrations at international trade shows and conferences – both for the furniture sector and mechanical industries. Algreen have also been nominated for The Earthshot Prize 2024. The next steps are to scale up simulations to prove concepts further and refine materials before production is considered. The project will seek further funding and pursue patents for the products themselves.