3DCarbide

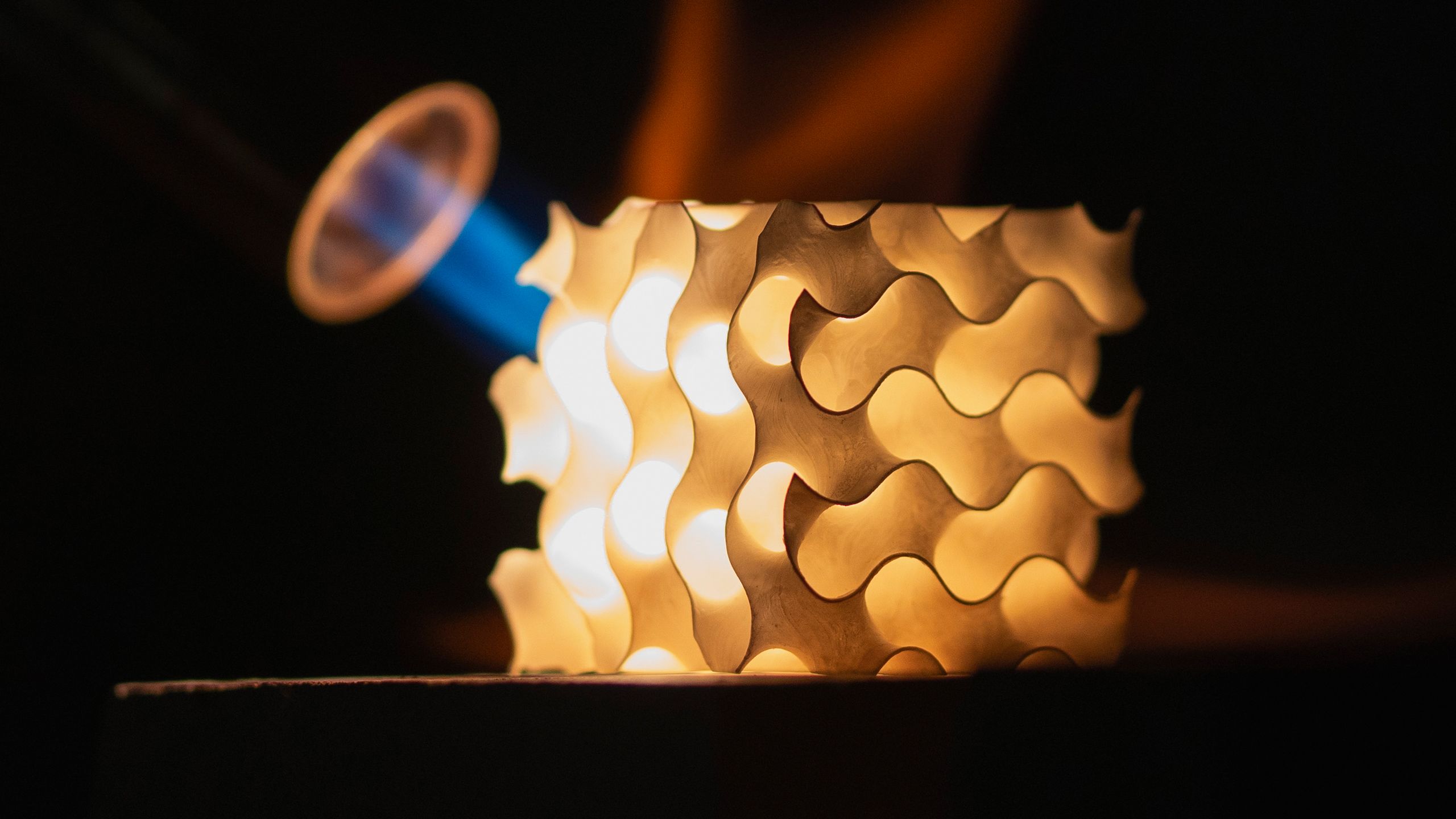

Photocentric Ltd have developed an effective method for printing dense silicon carbide parts for use as industrial heating elements, bringing the potential for parts that are better by design and can deliver heat more efficiently, with lower energy usage.

3DCarbide

Photocentric Ltd have developed an effective method for printing dense silicon carbide parts for use as industrial heating elements, bringing the potential for parts that are better by design and can deliver heat more efficiently, with lower energy usage.

Silicon carbide (SiC) was chosen because of its strong abrasion and chemical resistance, as well as its excellent thermal resistance and conductivity.

These exceptional properties make SiC ideal for a wide variety of applications but make it correspondingly hard to machine into optimal shape, limiting its applications.

Global demand for advanced ceramics is soaring, and there is a requirement for new technologies to provide them with lower energy at lower prices. The motivation for the 3DCarbide project is to support the wider use of ceramics so that, if SiC can be successfully printed, it will be possible to create heating elements and other products in any desired shape cost-effectively.

The project led by Photocentric Ltd, who, having successfully secured funding from the Transforming Foundation Industries (TFI) challenge, have developed an effective and innovative method for the manufacture of SiC parts using LCD-based 3D printing, that will widen the ability to use this outstanding ceramic in a greater variety of industries.

“This material has always been difficult to work with due to its abrasive nature and the toll it can take on the apparatus – preventing the use of existing injection moulding techniques,” says Dr Robert Young, Chemistry and Battery Team Leader at Photocentric. “At the same time, current 3D printing methods are very expensive, with only defined sized and shaped particles that can be used. This gave us an opportunity to find a more efficient and cost-effective production method to make the use of SiC far more widespread.”

“This solution helps reduce the cost and energy associated with silicon carbide parts, potentially making any geometry for the foundation industries and others to benefit from.”

The project aimed to demonstrate an innovative additive manufacturing method. It uses visible light selectively passing through LCD screen-based printers to make parts that will be subsequently infiltrated with silicon to bond with residual carbon to densify the parts to become usable silicon carbide. “The method not only offers energy benefits by removing the need for high-energy conventional manufacturing techniques but also reduces potential part costs,” adds Young. “This is because the printing process can utilise cheaper, irregular-sized particles. It also creates parts with dimensional freedom that can perform better and can have potentially thinner walls, producing a higher-quality part and a more scalable solution overall.”

When it came to results, the 3DCarbide project could print using these very dark materials, as previously unsuccessful, these printers had absorbed the light and failed to deliver viable curing. This moved the idea itself from theory to practice. This initial success also allowed the project to move to the next stage of sintering the materials and completing various optimisation processes.

“The early results were very promising, as we proved we could cost-effectively make viable, accurate and dense parts,” Young comments. “Additionally, by improving the flowability of the resin composite, we were able to reduce wear and tear on the printer itself. These parts have truly showcased the benefits of this novel manufacturing technique.”

The project partners are now moving forward with the concept to optimise the sintering process with specific applications. Further funding may be sought to manufacture, test, and validate these applications.

The project aimed to demonstrate an innovative additive manufacturing method. It uses visible light selectively passing through LCD screen-based printers to make parts that will be subsequently infiltrated with silicon to bond with residual carbon to densify the parts to become usable silicon carbide. “The method not only offers energy benefits by removing the need for high-energy conventional manufacturing techniques but also reduces potential part costs,” adds Young. “This is because the printing process can utilise cheaper, irregular-sized particles. It also creates parts with dimensional freedom that can perform better and can have potentially thinner walls, producing a higher-quality part and a more scalable solution overall.”

When it came to results, the 3DCarbide project could print using these very dark materials, as previously unsuccessful, these printers had absorbed the light and failed to deliver viable curing. This moved the idea itself from theory to practice. This initial success also allowed the project to move to the next stage of sintering the materials and completing various optimisation processes.

“The early results were very promising, as we proved we could cost-effectively make viable, accurate and dense parts,” Young comments. “Additionally, by improving the flowability of the resin composite, we were able to reduce wear and tear on the printer itself. These parts have truly showcased the benefits of this novel manufacturing technique.”

The project partners are now moving forward with the concept to optimise the sintering process with specific applications. Further funding may be sought to manufacture, test, and validate these applications.