EnviroAsh: Development new waste-derived raw materials for the Foundation Industries

“Working across multiple manufacturing industries creates an industrial symbiosis which not only reduces the amount of waste sent to landfill, but also reduces the need to mine or quarry virgin raw materials. In many cases, it can cut energy requirements and CO2 emissions, too.”

A cross-industry approach

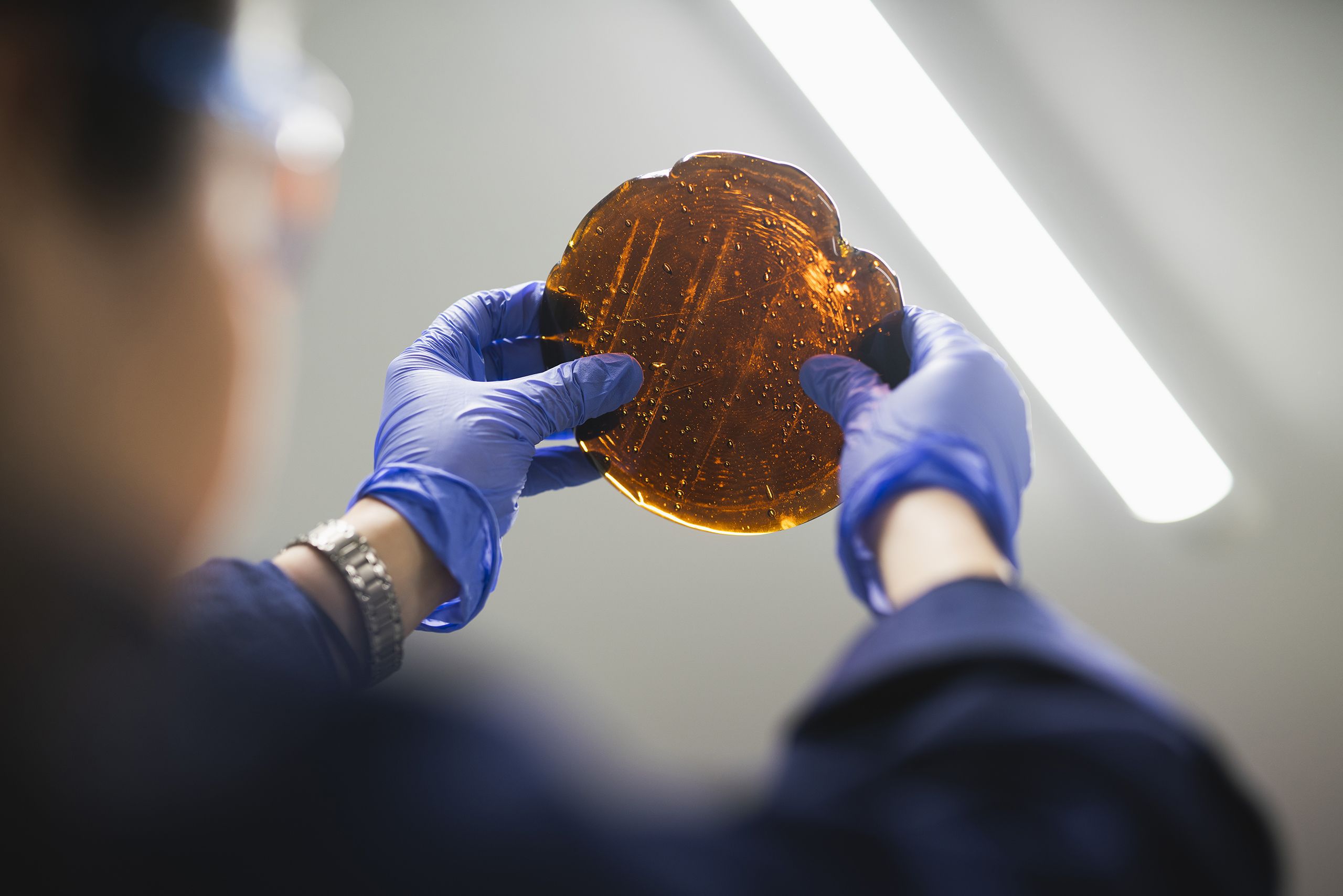

With funding from the Transforming Foundation Industries challenge, the EnviroAsh project brought together partners from six Foundation Industries – glass, ceramics, steel, paper, cement and chemicals – as well as the energy sector, academia and the waste and raw material supply chain, to examine waste streams across the industries and identify where they could potentially be reused.

“At GTS, we explored using biomass bottom ash from Biomass Powerstations and slate tailings in the manufacture of glass articles, such as containers, fibre glass and windows,” explains Holcroft.

“In trials, we were able to add up to 10% additions of ash materials to green and amber glasses (with small additions to flint glass) and similar amounts of the slate materials. This creates energy savings of 2-5% and associated CO2 savings of 3-10%.

“We were also able to add around 1–2% of slate tile waste to lead crystal, resulting in potentially more environmentally friendly drinking-ware.”

Other partners explored the use of different waste streams:

- Saica Paper UK identified opportunities for ash from its incinerators – themselves fired by waste paper sludge and pulp – as secondary raw material.

- Wienerberger Building Solutions explored whether by-products from other industries, particularly ashes, could be used as a direct replacement for the clay used in its bricks and roof tiles.

- Hanson UK investigated using slate tailings in its cement production.

- Encirc Ltd investigated the use of biomass ash and slate tailings as raw materials in container glass.

- Sheffield Hallam University and The University of Sheffield explored the use of biomass ash, slate waste and by products from mineral processing in glass, clay ceramics and cement.

- Power Minerals and Drax investigated supply and logistics for biomass ashes.

- Glass Futures provided support with dissemination.

Matchmaking software tool

The project team created a detailed inventory of the composition of waste streams, as well as an inventory of raw material requirements from the different industries in the project. These were then used to develop a simple ‘matchmaking’ software tool to identify where waste materials might be a suitable substitute for raw materials.

The project also investigated methods to scale up the processing of waste materials, taking it from early lab tests through to trials of 1,000 tonnes. “The project went beyond the simple proof of principle that these materials worked, investigating how processes could be developed to deliver consistent quality materials in sufficient quantities and in a commercially viable way,” says Holcroft.

“It also examined business models to identify the environmental and economic benefits of using these materials on an industrial scale.”

The cross-sectoral approach has been key to EnviroAsh’s success, and the next step is further disseminating the projects findings across the Foundation Industries to encourage more collaboration. “We have had a lot of interest from industry, particularly the biomass power sector. There’s a strong appetite for finding a home for these waste materials,” says Holcroft.

“With increasing pressure to become more sustainable – and reduce energy consumption – there’s no better time to look into solutions to expand circular economy and the availability of secondary raw materials through this type of industrial symbiosis.”