EPSRC: Investing in discovery research that drives innovation to deliver a resilient future

Long-term EPSRC research and training investments develop new behaviours and solutions that anticipate, adapt and respond to an ever-changing world. These seven projects showcase researchers that are tackling some of the biggest global challenges - meeting the needs of present and future generations.

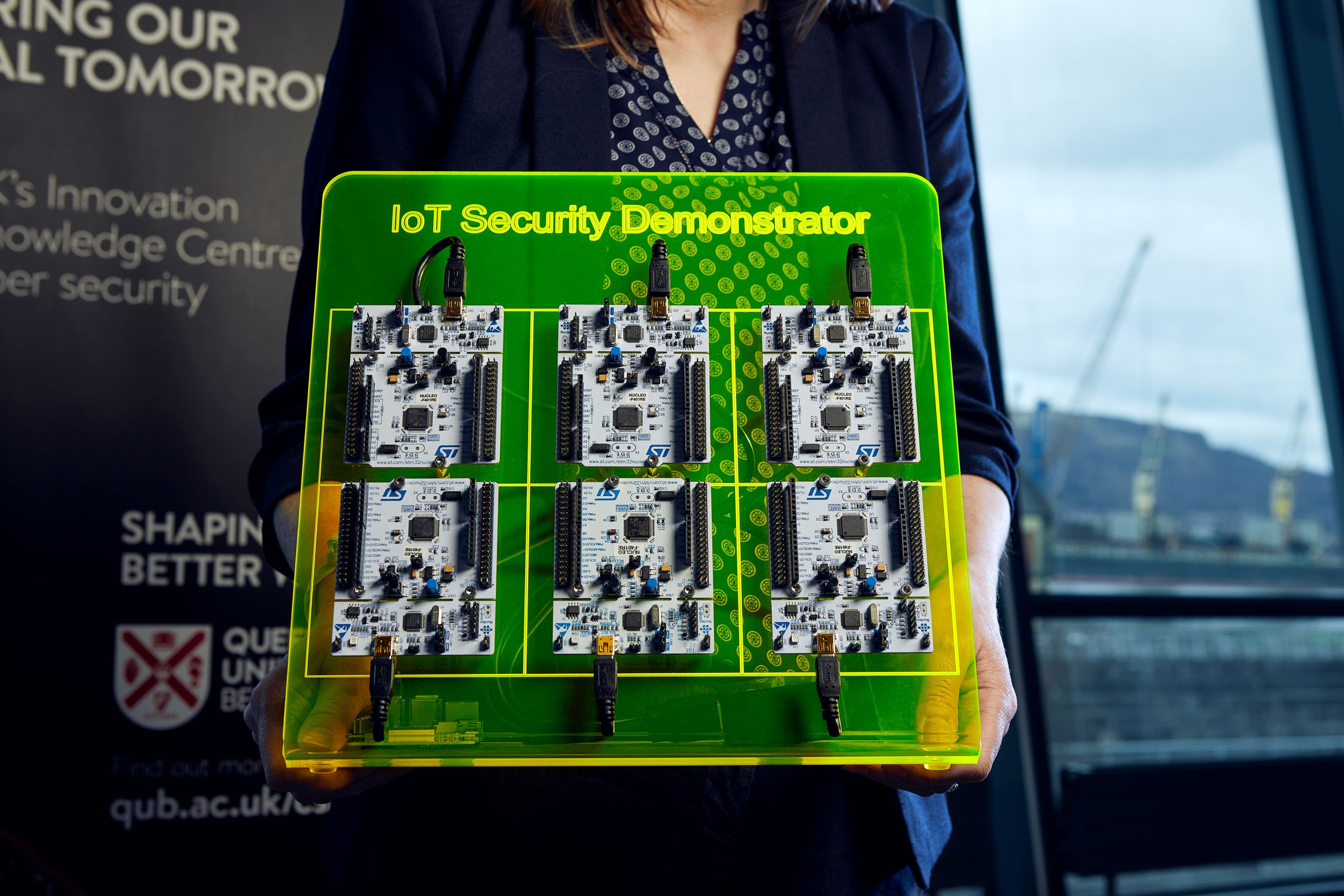

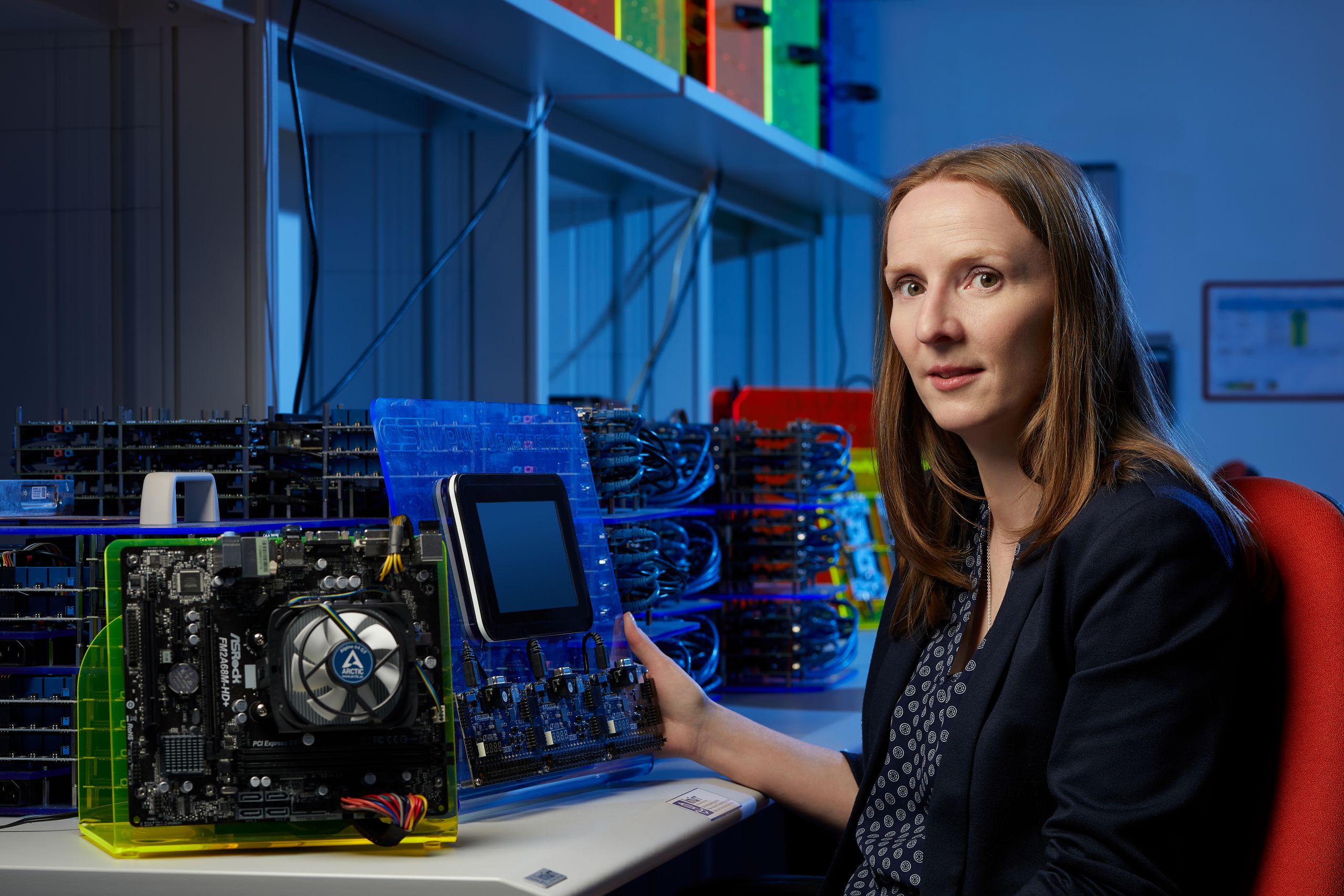

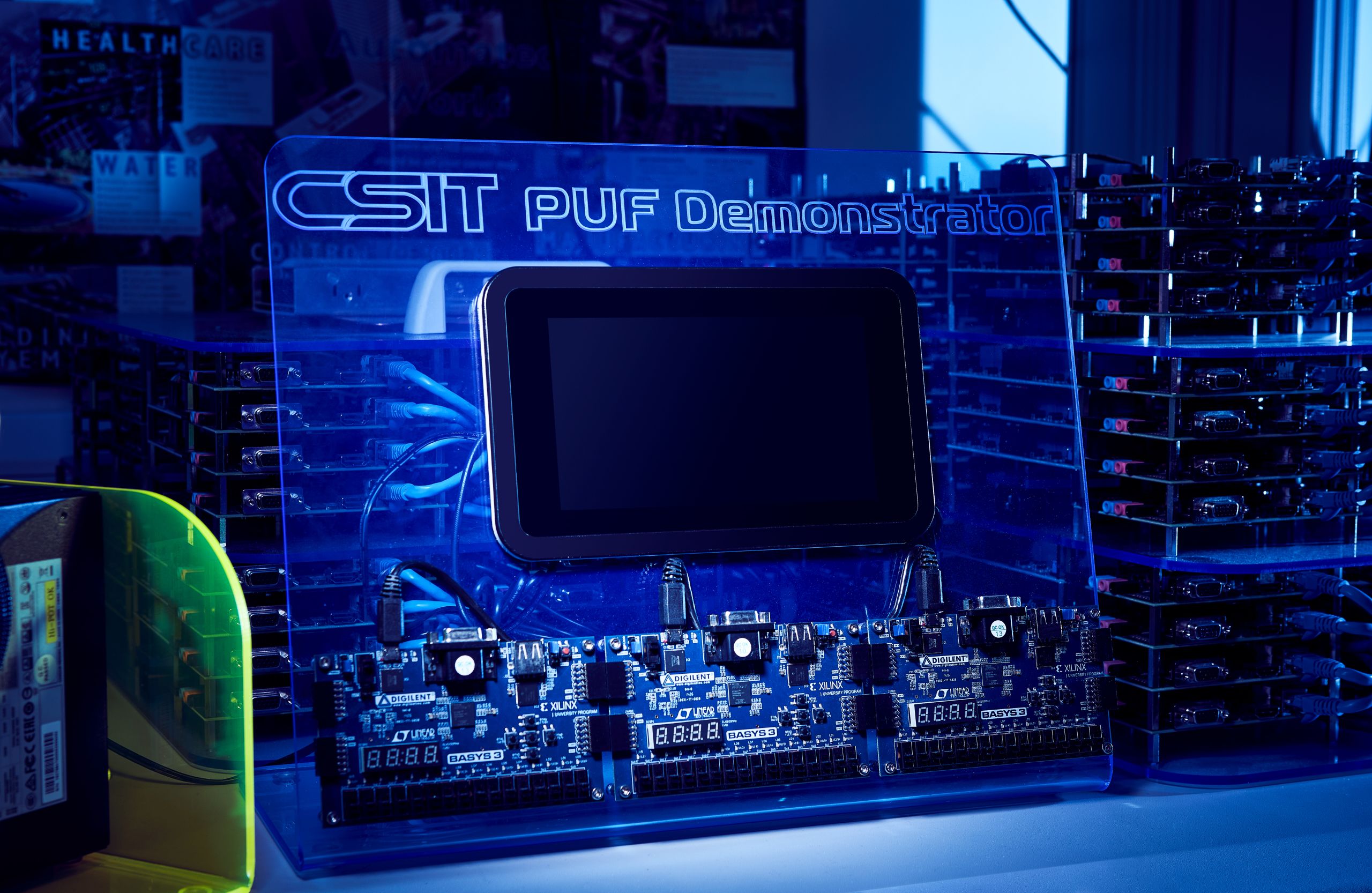

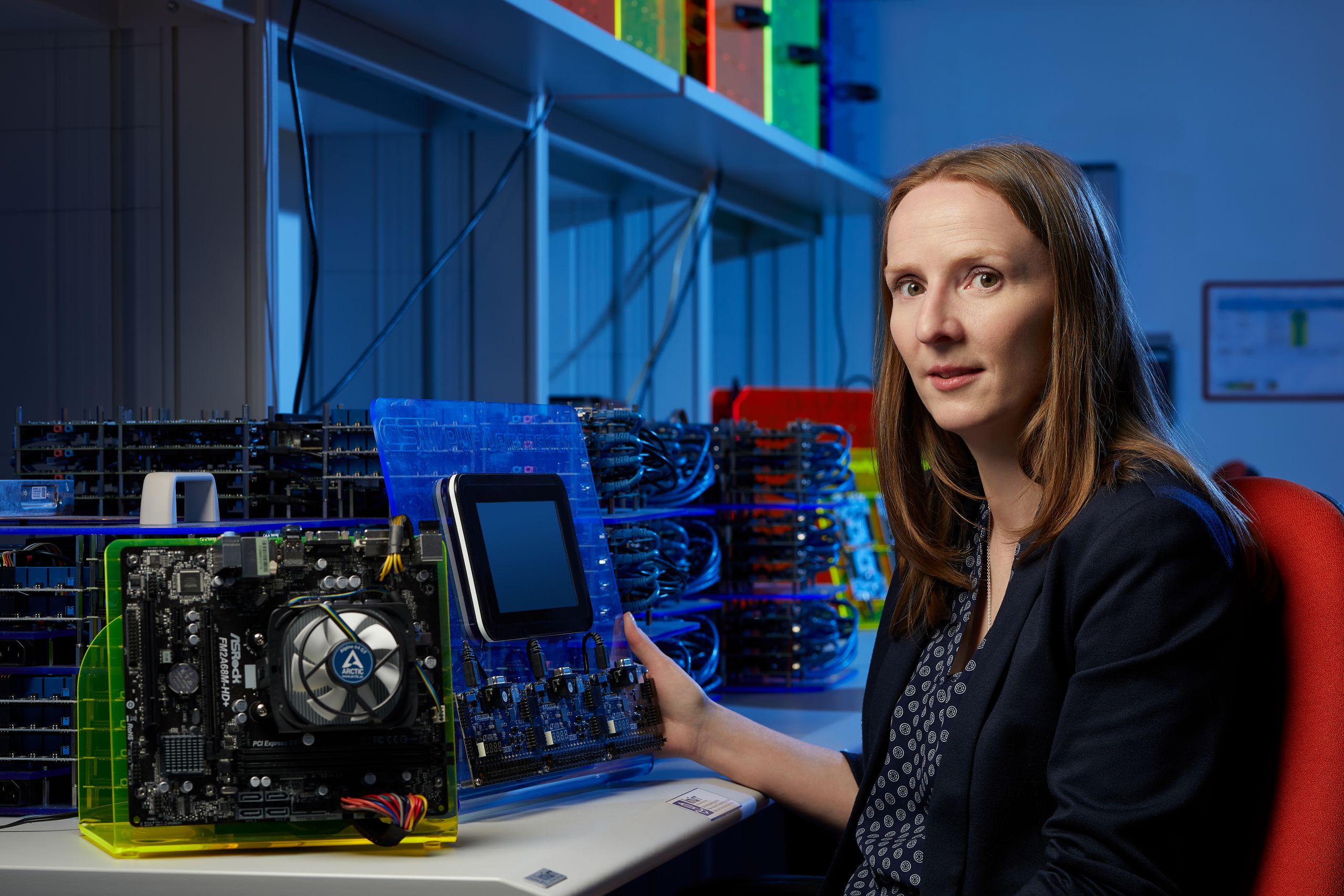

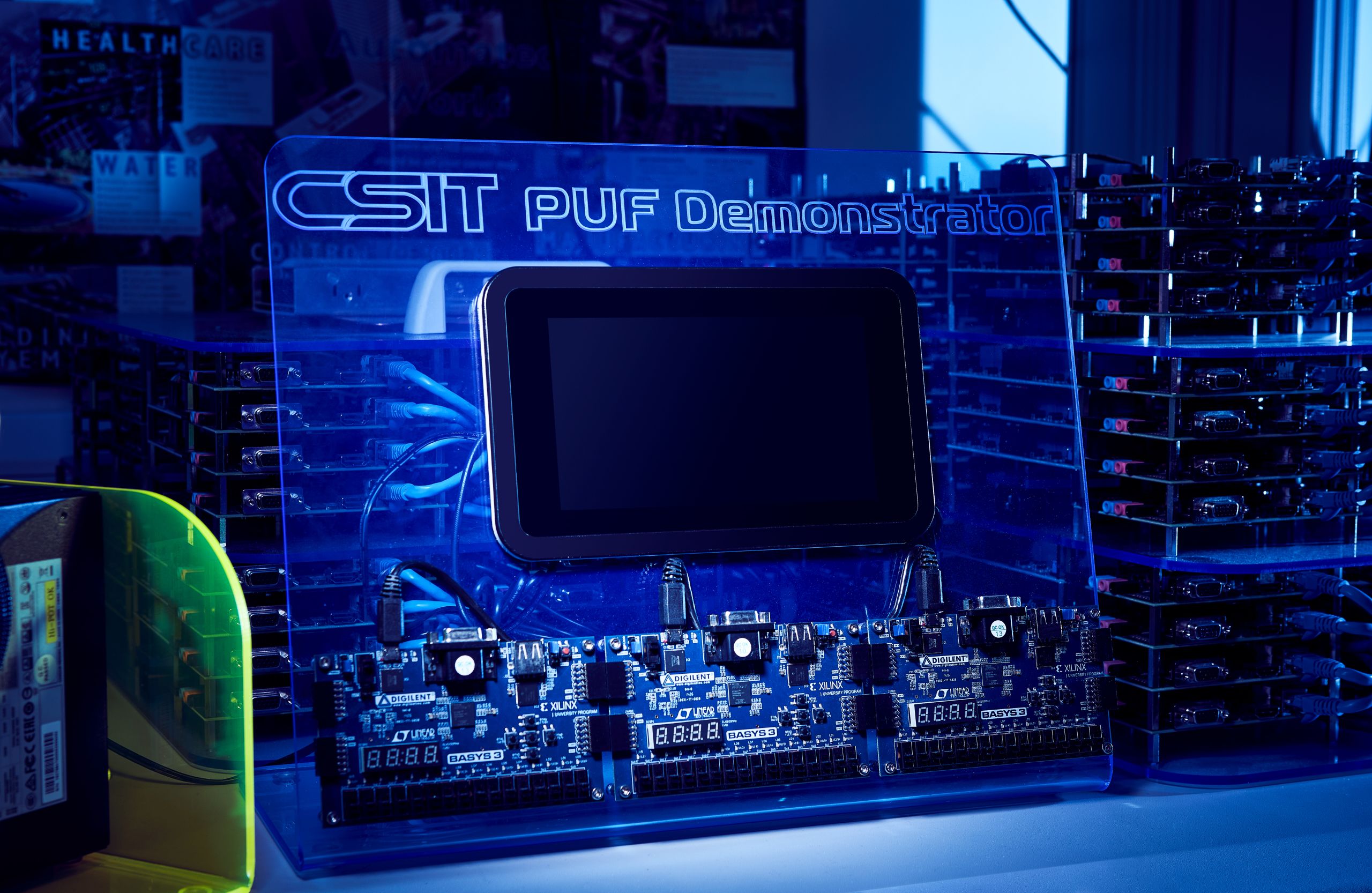

Keeping our data safe: Professor Máire O’Neill, Director, Centre for Secure Information Technologies (CSIT), Queen’s University Belfast (QUB)

Cybercrime costs the global economy an estimated $US2.9 million per minute. The Centre for Secure Information Technologies (CSIT) at Queen’s University Belfast was set up to meet this challenge, and has been supported for over a decade by EPSRC and Innovate UK.

CSIT’s Director, Professor Máire O’Neill, says: “Over the last 20 years, effective cybersecurity has become one of society’s critical needs – helping to keep our data safe, ensuring our mobile devices are free from malware, and defending vital digital infrastructure against hostile attack.

“At QUB we tackled this need head-on and, in doing so, helped to boost economic renewal in Belfast and Northern Ireland.”

CSIT has helped to attract over 100 high-tech companies employing over 2,000 people to the region. It has also fostered collaborations across government and industry, including Cisco, IBM and McAfee; spawned several spin-out companies and developed real-world innovations against cybercrime in sectors ranging from finance to defence.

Widely regarded as one of Europe’s leading cryptography experts, Professor O’Neill is the inventor of a high-speed silicon security chip used in more than 100 million TV set-top boxes.

PicoPuf, a spin-out company co-founded by Professor O’Neill, a former UK Female Inventor of the Year, is developing encryption technology that guarantees that even the smallest microchip can be equipped with strong, unique authentication. The company was named Northern Ireland’s most promising startup in terms of global commercial potential.

Professor Máire O’Neill

Professor Máire O’Neill

Non-invasive ventilators for critically ill COVID-19 patients: Professor Rebecca Shipley and Professor Tim Baker, UCL

In March 2020 the coronavirus pandemic began to spread around the globe. As hospitals and intensive wards filled up, doctors needed effective therapies and fast. There was also a lack of equipment to assist the breathing of critically endangered patients.

This led a UCL team to join forces with Mercedes AMG-Formula 1 engineers on the ultra-rapid re-engineering and production of vital CPAP ventilator devices to help treat patients in intensive care – technology that would prevent around 50% of patients from needing invasive mechanical ventilation. The team’s design gained regulatory approval in just ten days – a process that can take years.The UCL team was co-led by Professor Tim Baker and Professor Rebecca Shipley. Professor Shipley, a mathematician turned mechanical engineer, was uniquely placed to work on the project, which resulted in 10,000 breathing aids being manufactured within four weeks, with 1,200 produced per day at one point. The devices were subsequently deployed to over 130 NHS hospitals.

To contribute to the extensive global need, in particular in low and middle income countries, the team released their blueprints for free to enable manufacturing hubs to be set up in other countries. The team also worked with charities and the UK government to send devices to countries in urgent need. The CPAP devices are now in use in hospitals in around 20 countries including Peru, Mexico, Paraguay, South Africa, Palestine, Uganda, Pakistan, India and Nepal.

Professors Tim Baker and Rebecca Shipley

Professors Tim Baker and Rebecca Shipley

Professor Shipley

Professor Shipley

Professor Tim Baker

Professor Tim Baker

CPAP device

CPAP device

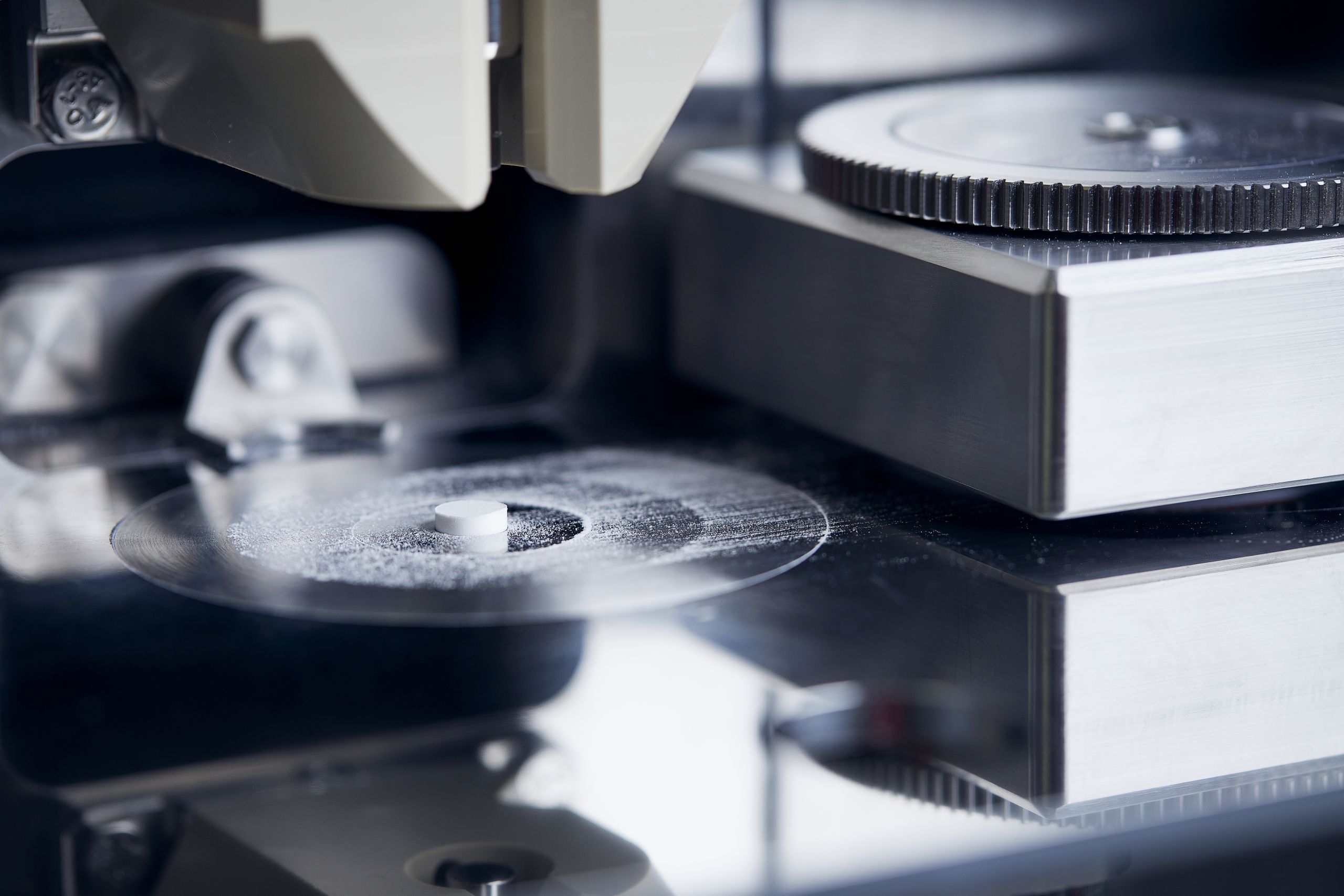

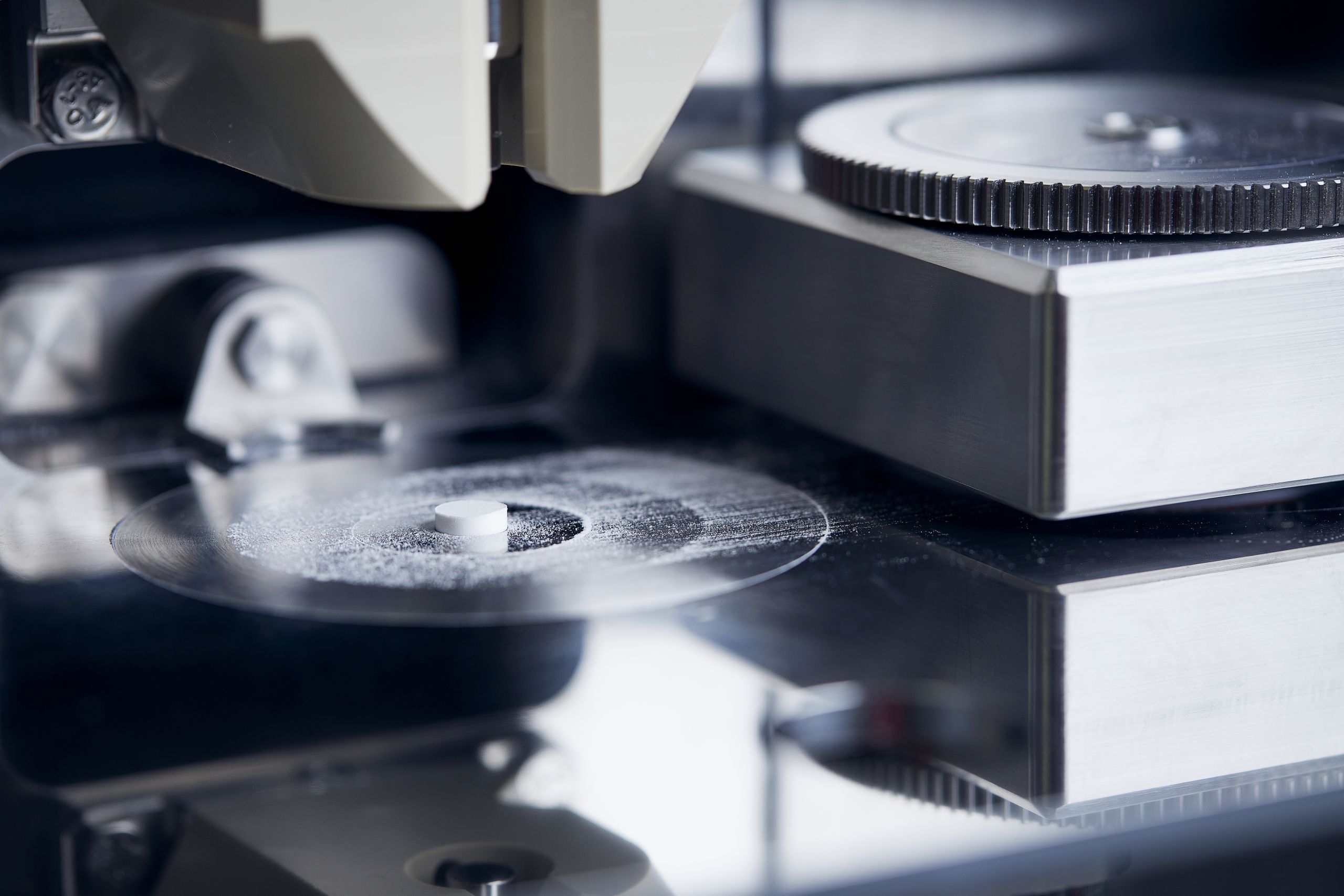

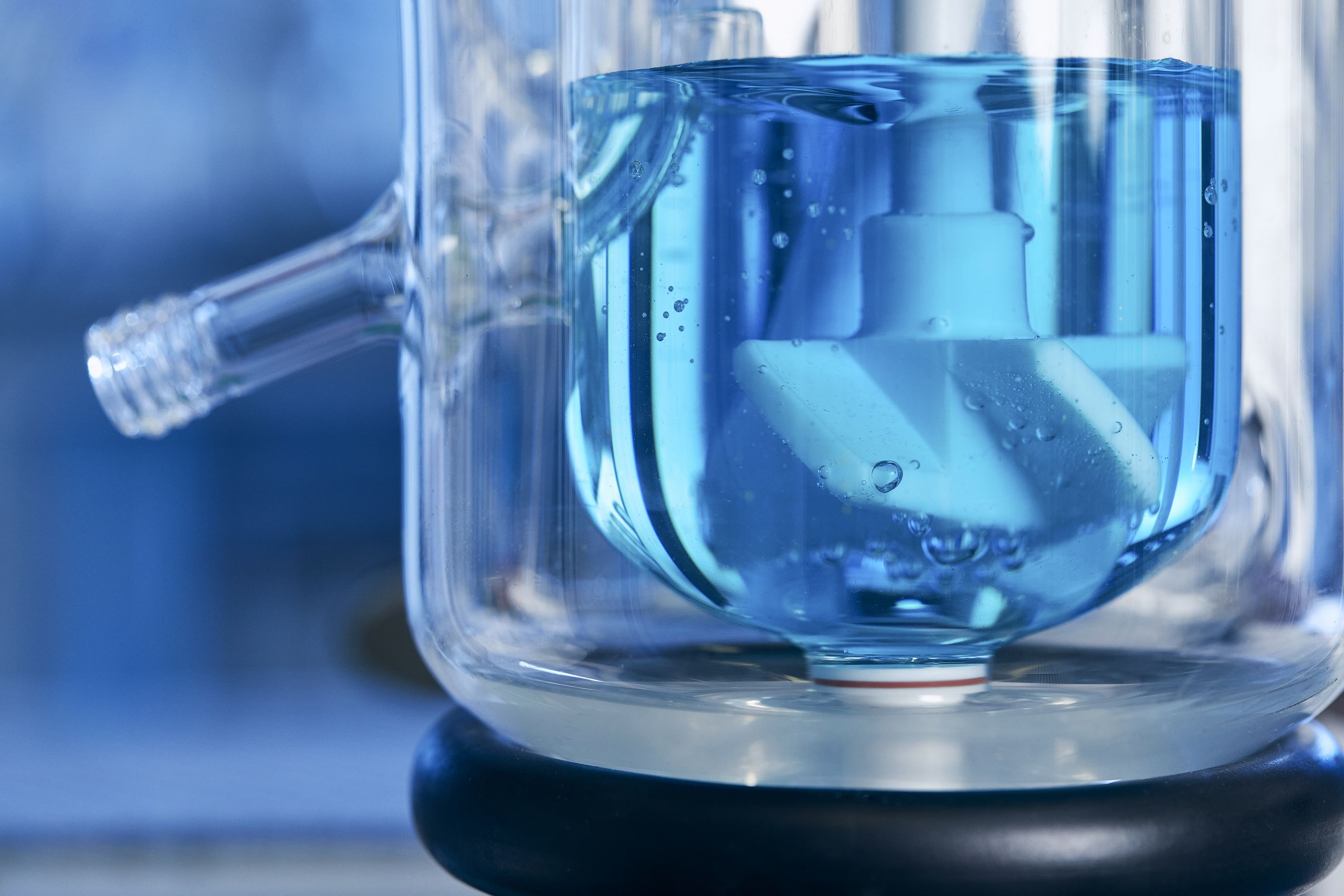

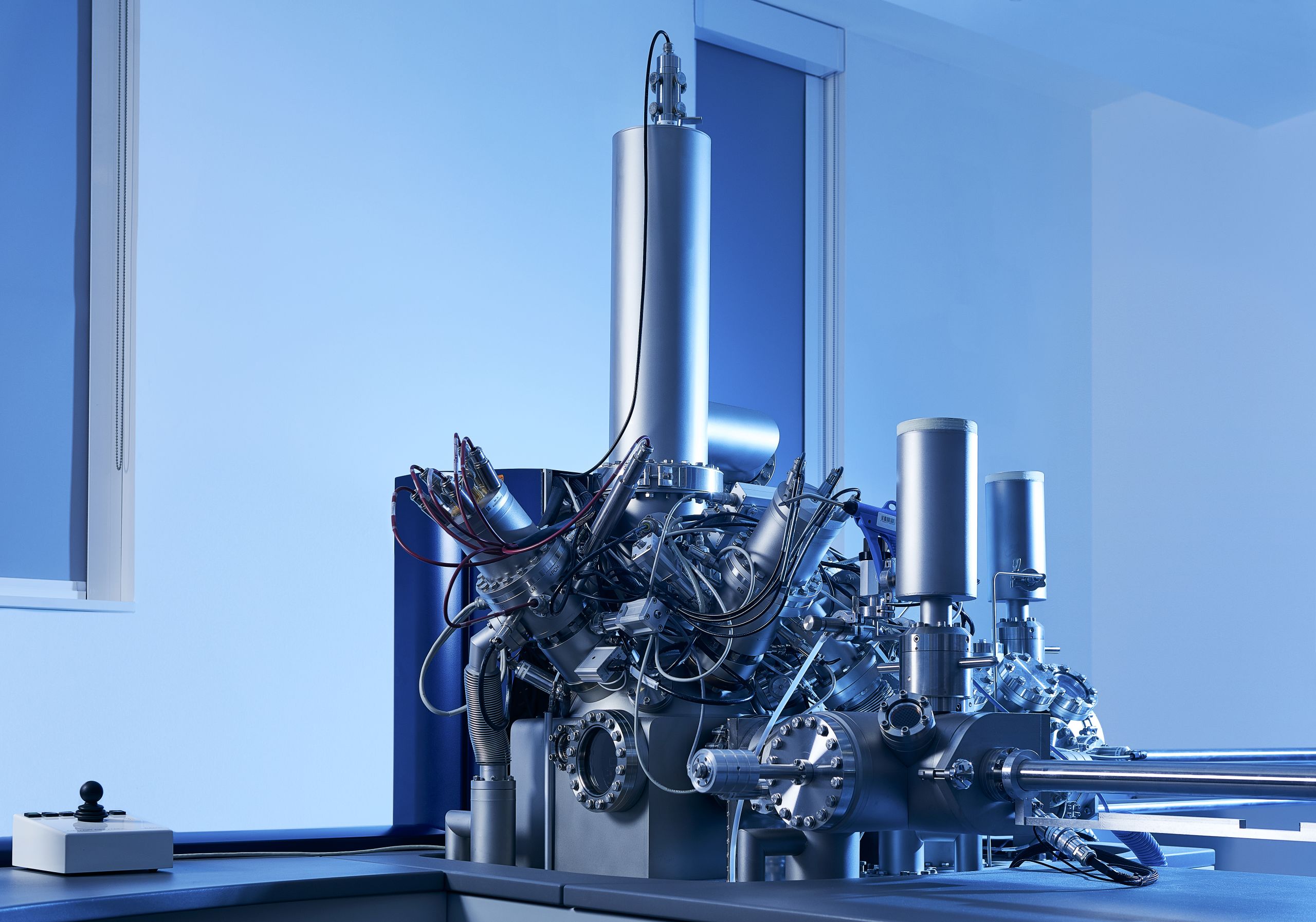

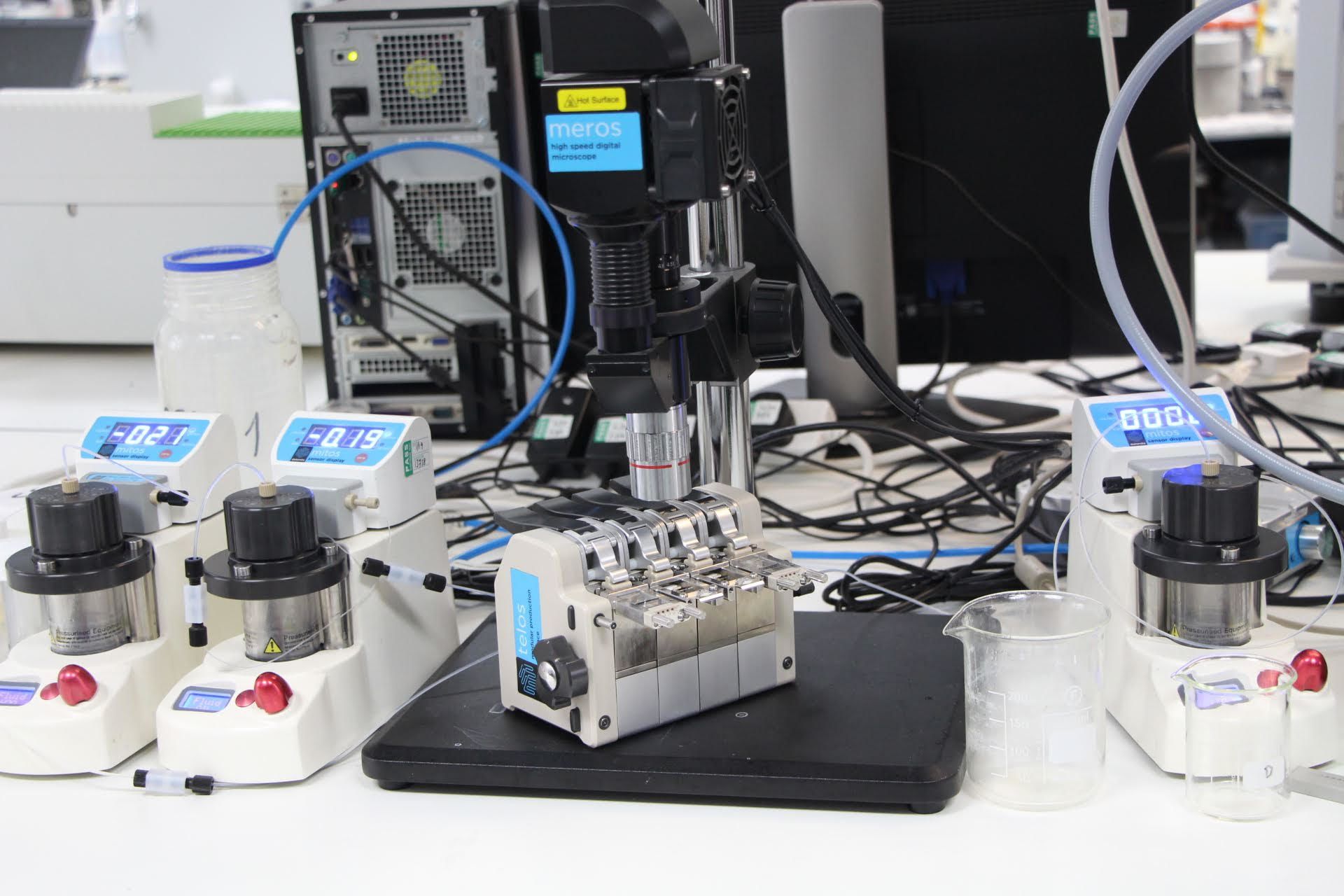

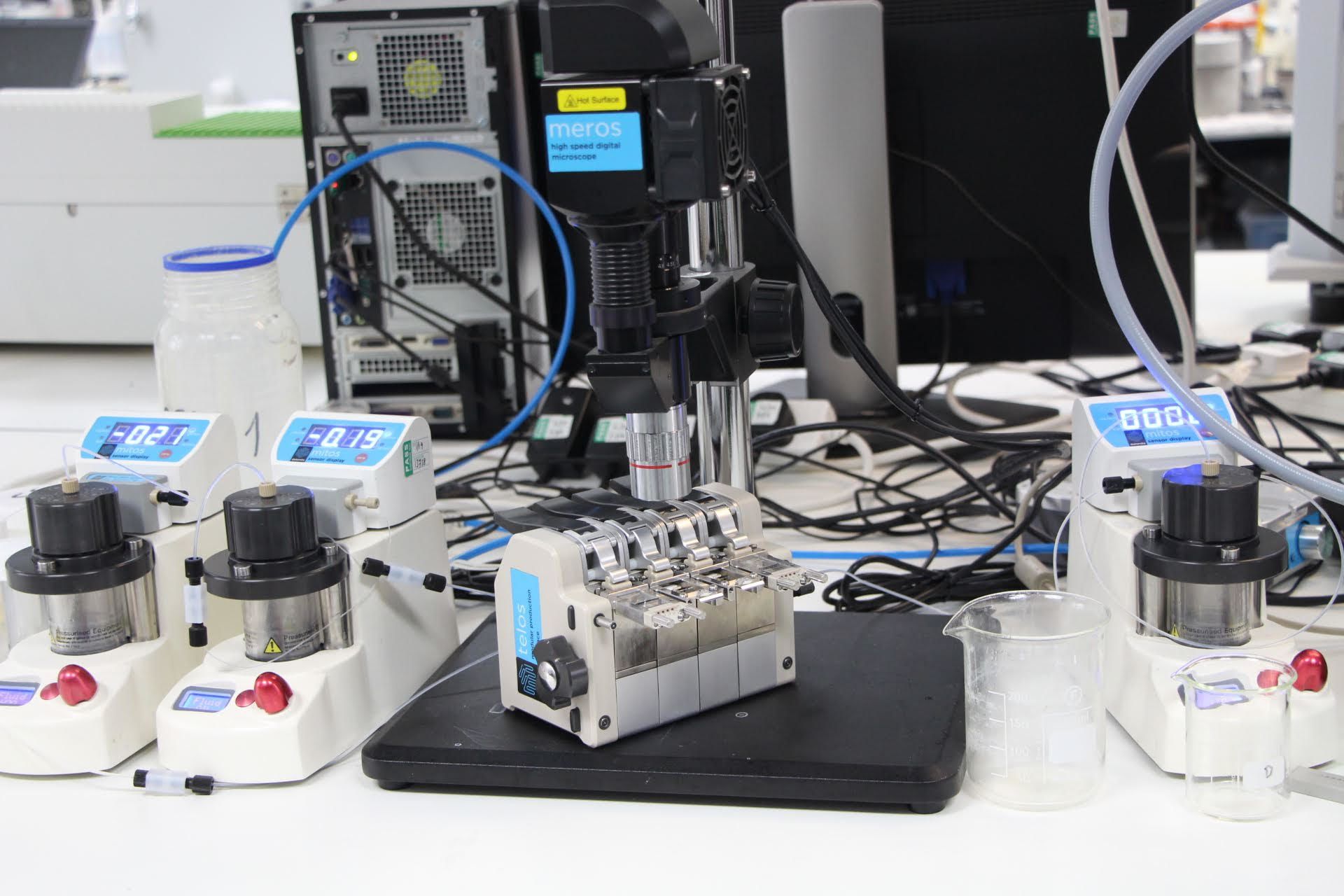

Future medicine manufacture: EPSRC Future Continuous Manufacturing and Advanced Crystallisation Research Hub (CMAC), University of Strathclyde

Despite incredible progress in all aspects of healthcare, the way we make medicines, particularly tablets, has changed very little over the last 100 years.

Valuable resources are wasted through outdated, complex and time-consuming manufacturing techniques which are holding back developments in personalised medicine while limiting our resilience to new and emerging challenges such as an ageing population and our increasing resistance to antibiotics.

In 2010, to address these and many other challenges, EPSRC invested in the University of Strathclyde-based Future Continuous Manufacturing and Advanced Crystallisation Research Hub (CMAC).

Led by Professor Alastair Florence, CMAC today comprises seven leading UK universities, eight global pharmaceutical partners and 17 technology companies. In essence, CMAC’s mission is to enable the pharmaceutical and chemical industries to make high-quality drug substances and particle-based products such as tablets through continuous, end-to-end manufacturing. This process dramatically improves efficiency, reduces waste and minimises batch-to-batch variability.

Fundamental to the CMAC model is the development of a ‘digital twin’ of the manufacturing process using advanced computer modelling and simulation.

Acting as a kind of flight simulator, the digital twin enables scientists to virtually design a full-scale manufacturing process as well as to trial their formulations in virtual reality before they head to the development labs.

During manufacture, the digital twin becomes the autopilot, providing enhanced feedback and control; using real-time data to maintain control predictively, not reactively. In this way, processes that once took weeks can be performed in a matter of hours.

The net result is reduced wastage of materials – including expensive active pharmaceutical ingredients – and a cheaper, faster, more efficient manufacturing process.

UKRI recently made a video about digital twinning at CMAC.

Dr Andrea Johnston - CMAC

Dr Andrea Johnston - CMAC

Fending off floods: Dr Maria Pregnolato, University of Bristol

In 2015 alone, the UK suffered disruption and losses of £1.6 billion due to floods – often resulting from the failure of ageing infrastructure such as river bridges. Dr Maria Pregnolato has devoted her career to addressing this urgent and ongoing threat to our resilience.

Supported by an EPSRC Early Career Fellowship, she is investigating urban UK infrastructure and natural hazards, particularly the impact of flooding on bridges and transportation systems. By giving towns and cities a better understanding of risk, her research is helping them manage threats to their resilience.

"To Dr Pregnolato, disasters such as urban flooding are not natural. They are products of political, social, socio-economic, technical and technological processes. A hazard can only become a disaster once it impacts on an unprepared society or community. The risk from natural hazards leads to communities being exposed by failing or inadequate infrastructure.

In multi-faceted research that combines hydraulics, civil engineering, computer modelling and economics, she is helping communities to manage flood risk by providing information about flood impact to the road network and bridges, as well as scenarios relating to the implications of flooded roads.

Maria’s fellowship aims to enable risk-based decision-making and prioritisation of limited funds for maintenance and enhancing national resilience. This will happen through the development of a more detailed national and regional assessment model for bridge failures from high river flows.

Dr Maria Pregnolato

Dr Maria Pregnolato

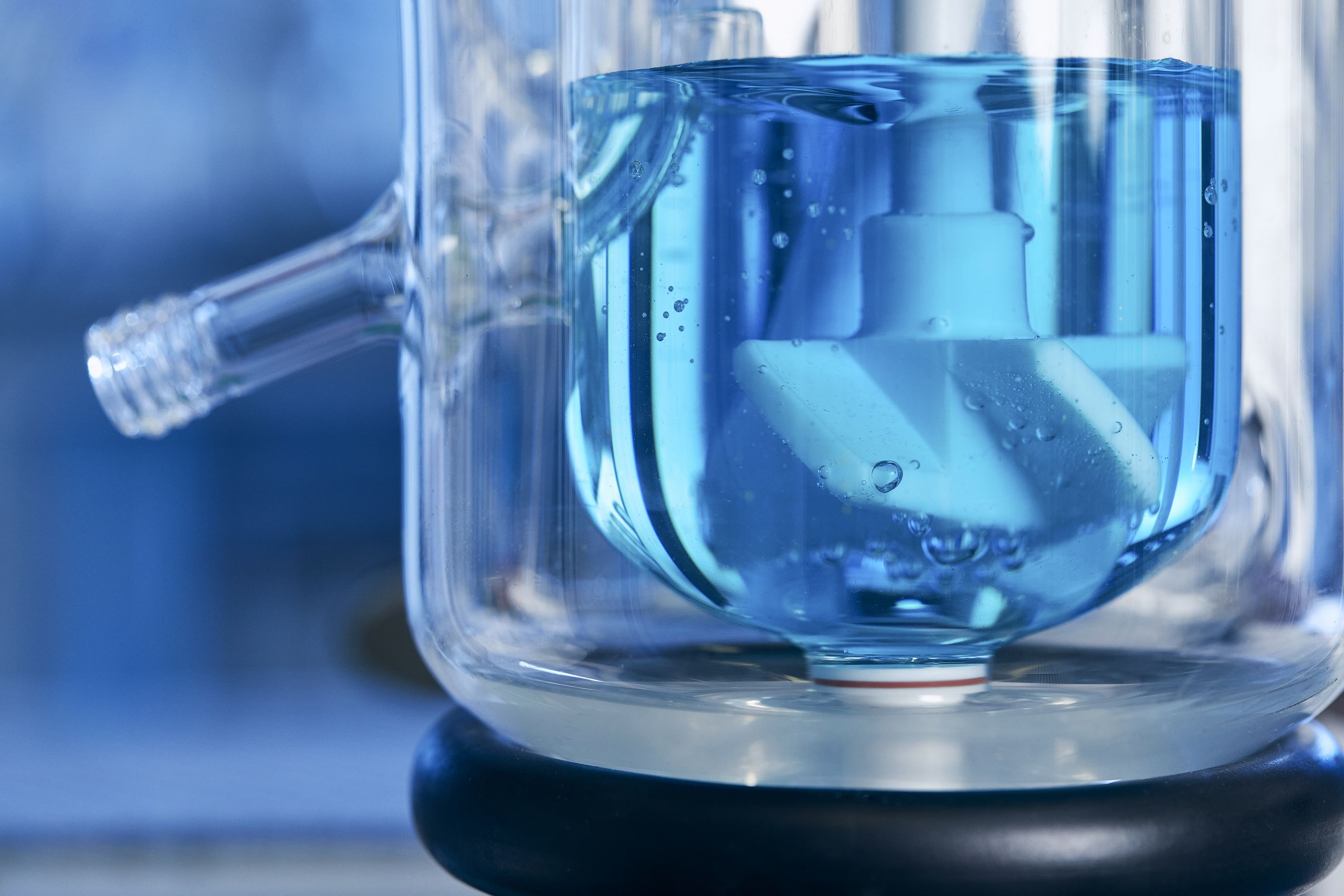

Infrastructure for Life: Professor Abir Al-Tabbaa, Director, EPSRC Centre for Doctoral Training in Future Infrastructure and Built Environment and Resilient Materials for Life Programme Grant. University of Cambridge.

Given the importance of infrastructure to modern human existence – from motorway bridges to hospitals – it is astonishing how little infrastructure materials and practices have changed.

Cement, for example, accounts for up to ten per cent of global carbon emissions and presents a very real threat to our resilience. Professor Abir Al-Tabbaa’s research at the University of Cambridge is dedicated to transforming construction materials like these.

But creating the low-carbon infrastructure of the future won’t happen overnight, and it is essential to invest in the development of the next-generation of engineers and innovators equipped with the knowledge and creativity to turn ideas into concrete reality.

To this end, Professor Al-Tabbaa leads the EPSRC Centre for Doctoral Training (CDT) in Future Infrastructure and Built Environment. Based at the University of Cambridge, this centre is equipping students with a versatile and cross-disciplinary skillset to meet the most complex infrastructure challenges. In turn, they are applying radical new thinking, leadership and approaches to transforming our infrastructure and built environment.

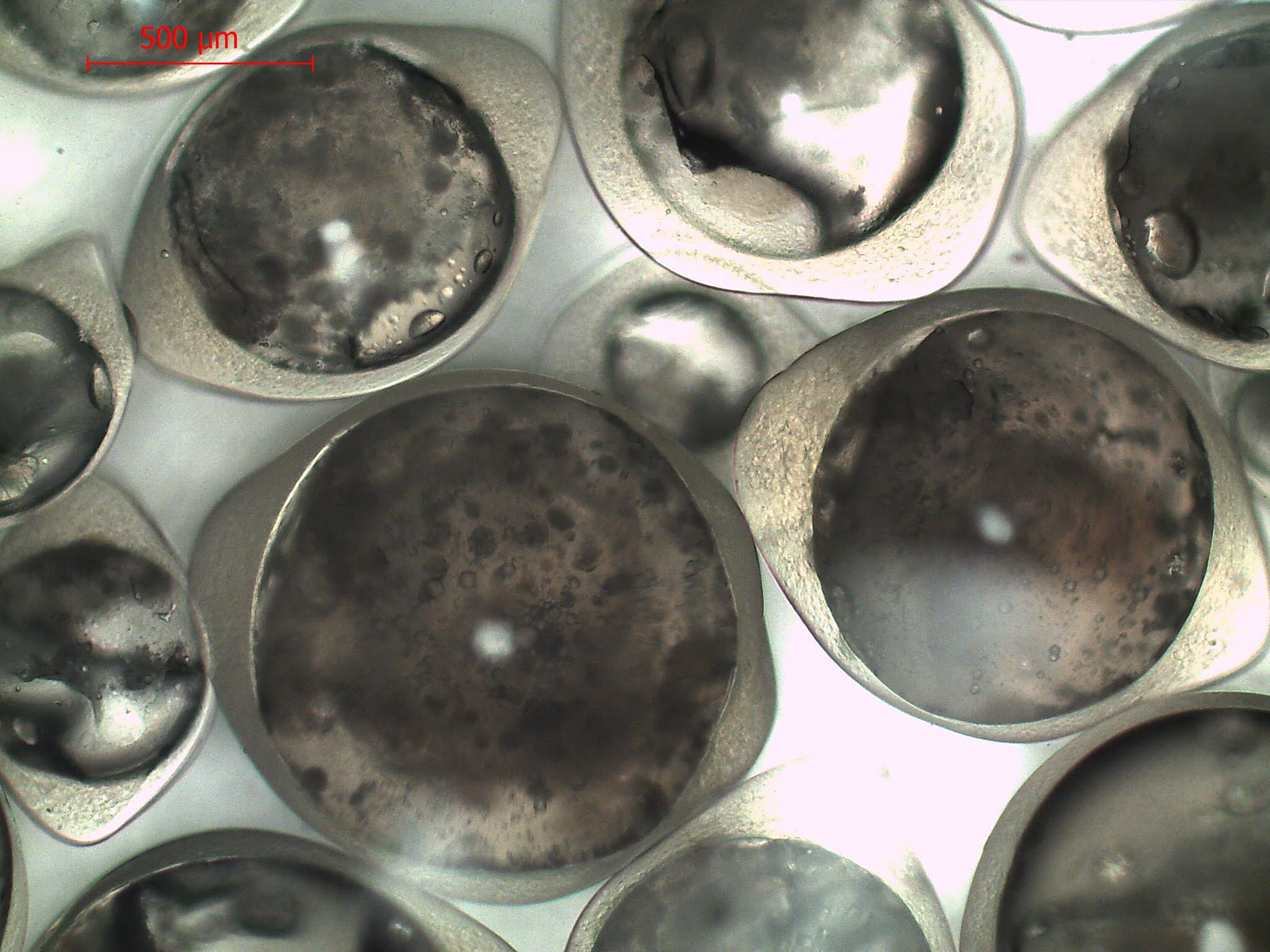

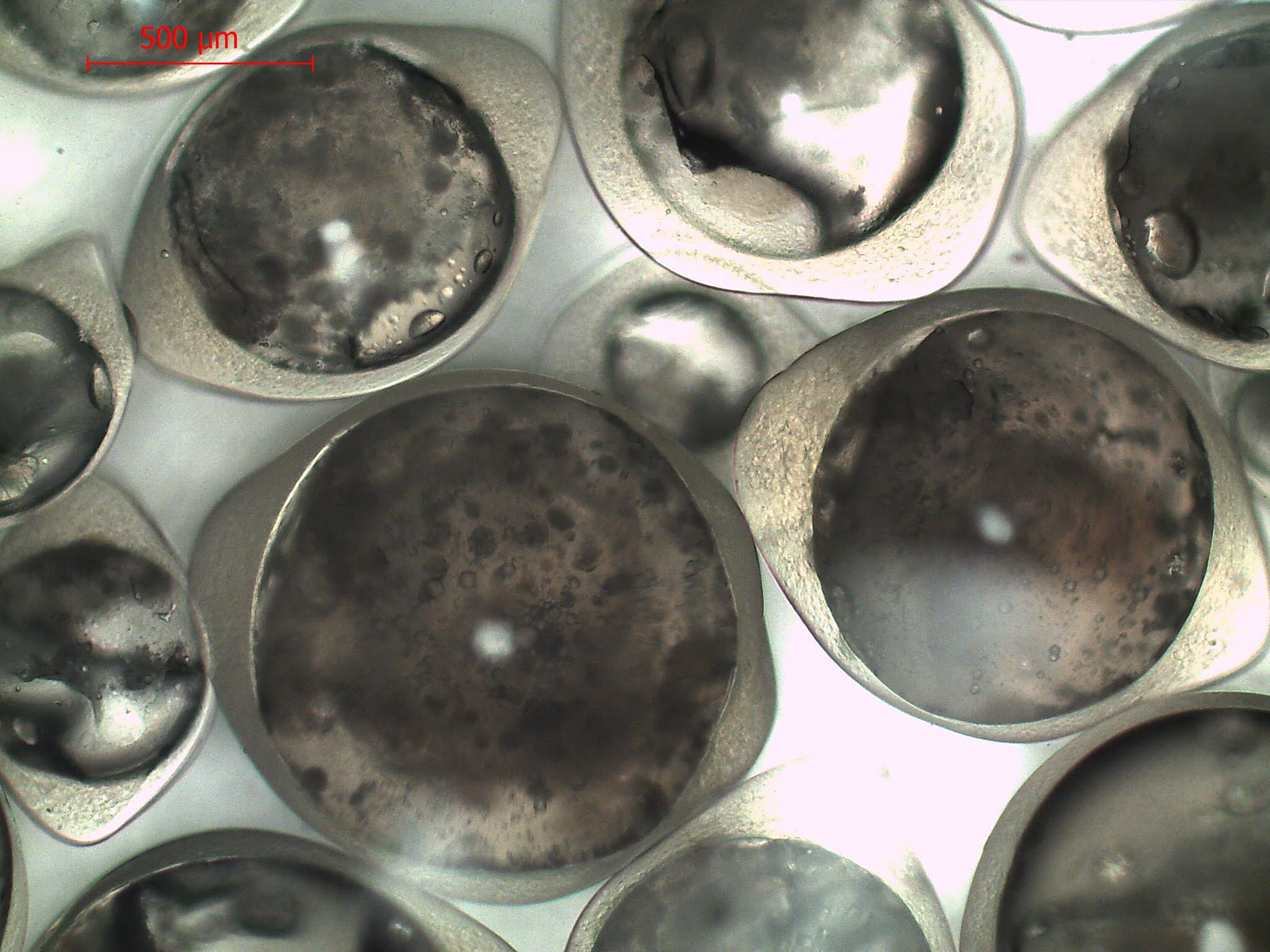

For example, students have been playing a key role in the EPSRC-funded multidisciplinary programme Grant Resilient Materials for Life, to develop concrete that can self-diagnose and self-heal when damaged. Innovative self-healing microcapsules were developed and implemented in the first full-scale field trials of self-healing concrete in the UK.

The research into self-healing concrete for low carbon infrastructure has also attracted the attention of some of the most influential leaders on Earth; leading to an invitation for Professor Al-Tabbaa to present the team’s work at the World Economic Forum in Davos.

Professor Abir Al-Tabbaa

Professor Abir Al-Tabbaa

Microcapsules with gum arabic/gelatine shell with sodium silicate core

Microcapsules with gum arabic/gelatine shell with sodium silicate core

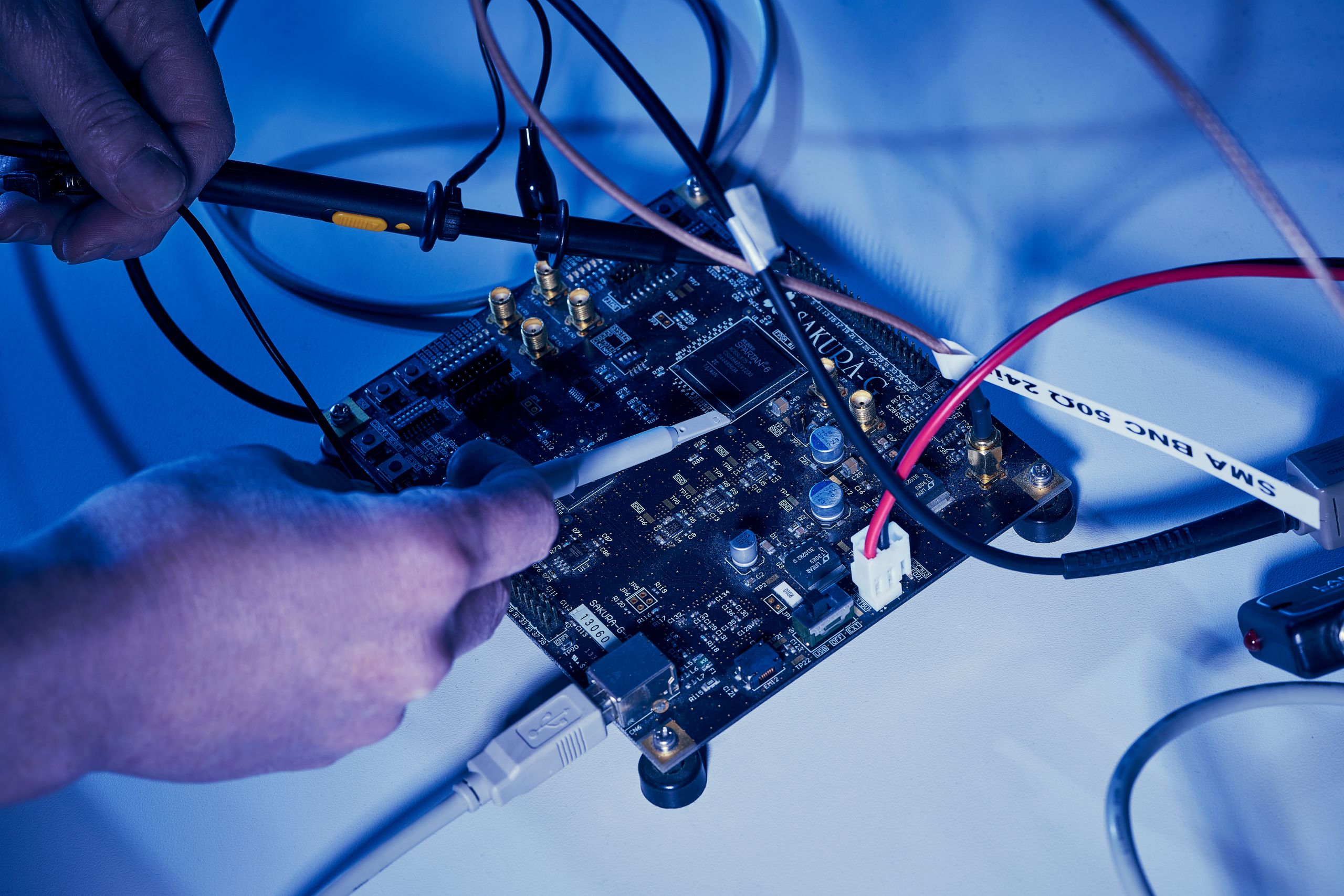

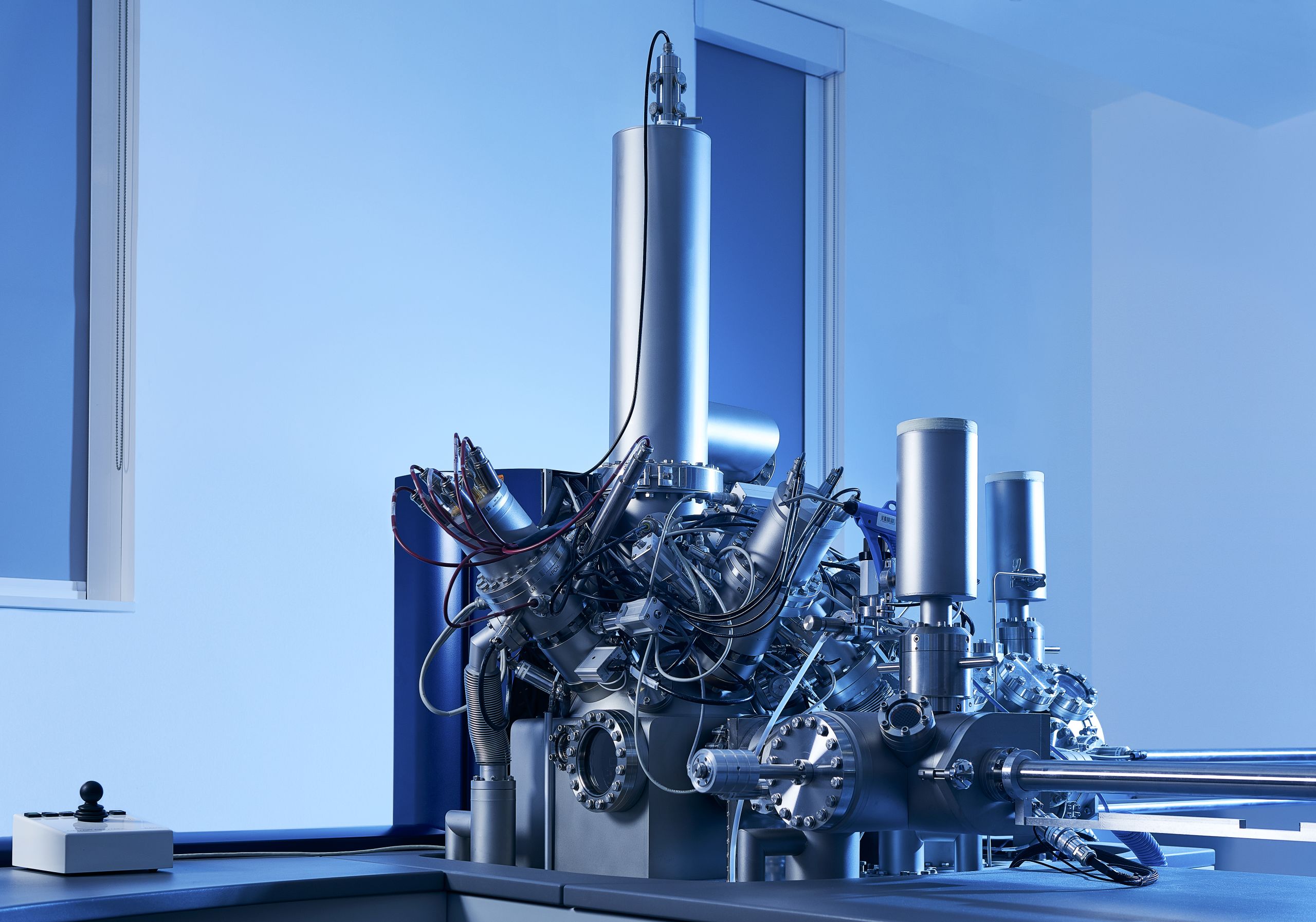

Energy efficient computing: Professor Bashir M. Al-Hashimi, King’s College London

In a world increasingly dependent on super-powerful but energy-hungry computer processors, Professor Bashir Al-Hashimi is at the forefront of research that’s breaking vital new ground in low-power computing; hardware-software co-design and the emerging field of battery-free computing through energy harvesting.

With long-term funding from EPSRC, he has led a number of interdisciplinary research programmes to develop and design everyday electronics and software, for use in devices such as smartphones and tablet computers, that do more for you and have longer, energy-efficient battery life.

Much of his research revolves around the challenges, opportunities and potential applications offered by what are known as ‘many core’ computers. We already use many core technologies in our dual, quad and octacore smartphones and laptops. These provide a glimpse of the future in which ‘embedded’ multi-core technologies will lead to ultrapowerful portable devices and super-smart technologies used in everything from ‘predictive’ traffic lights and intelligent MRI scanners, to smart domestic robots.

The key to the success of these technologies will be their low power consumption, which will pave the way to a dynamic ‘Internet of Things’ embedded in a new generation of systems that change the way we work, do business, shop, travel and care for ourselves.

Awarded a CBE in 2018 for services to engineering and industry, in 2020 Professor Al-Hashimi received the Faraday Medal from the Institute of Engineering and Technology and was elected a fellow of the Royal Academy of Engineering in 2013.

Professor Bashir M. Al-Hashimi

Professor Bashir M. Al-Hashimi

Professors Geoff Merrett and BashirAl Hashimi

Professors Geoff Merrett and BashirAl Hashimi

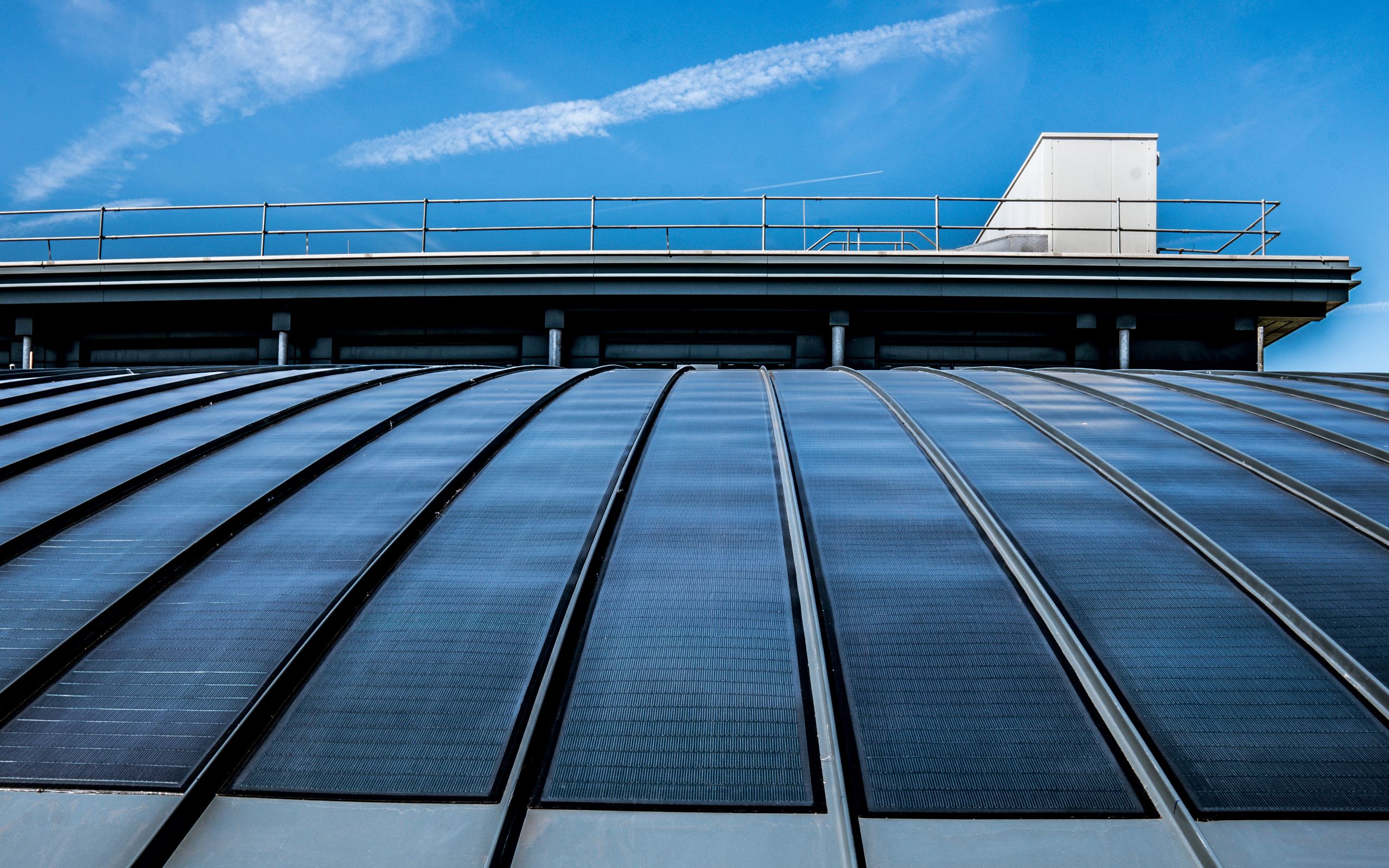

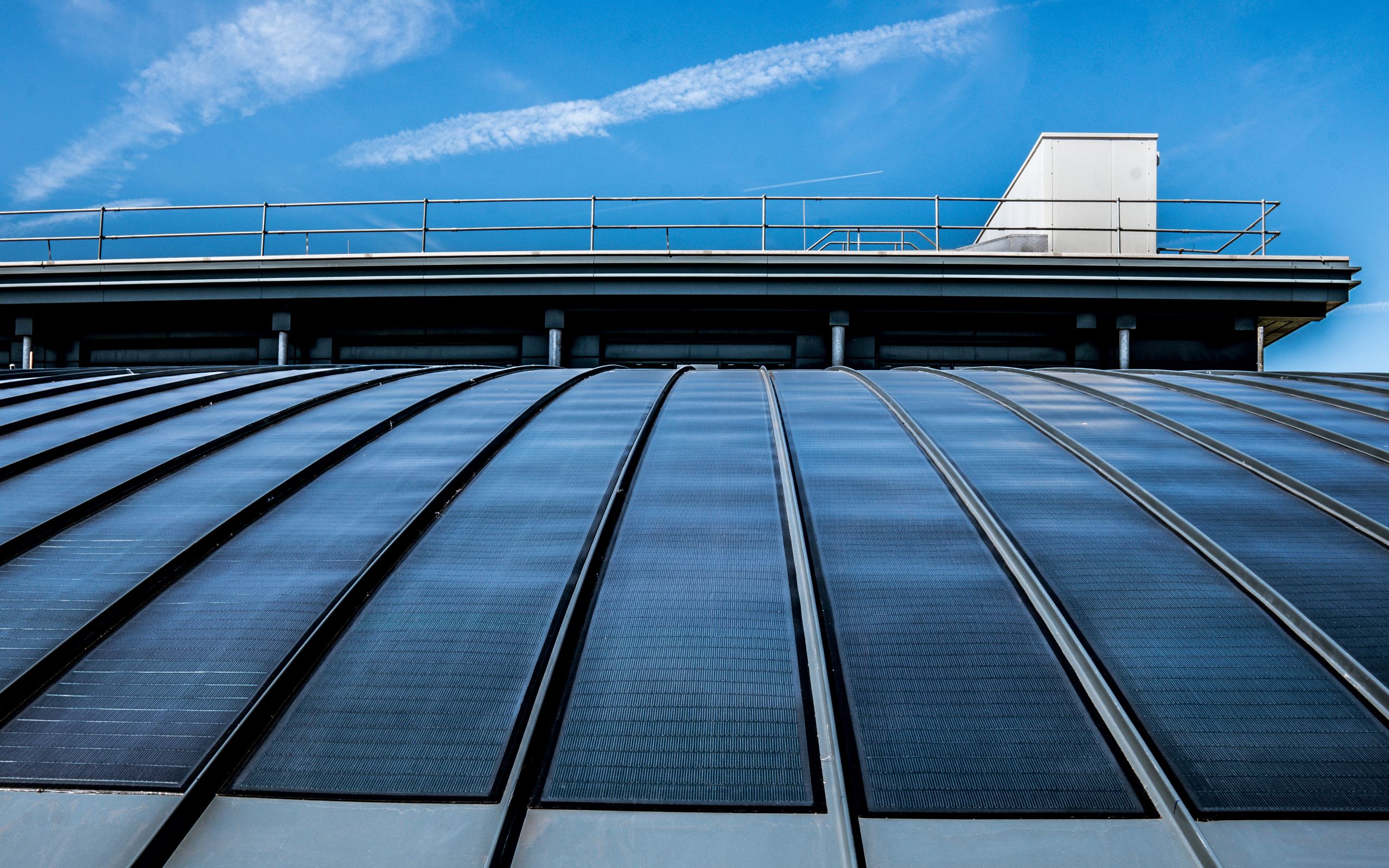

Paving the way for self-sufficient buildings: Professor Dave Worsley, SPECIFIC Innovation and Knowledge Centre, Swansea University

Buildings are energy-hungry, accounting for 39 per cent of global CO2 emissions. In the UK, almost 40 per cent of energy consumption and carbon emissions come from the way our buildings are lit, heated and used.

The solution is everywhere – sunlight. Every day the sun provides enough energy to power our planet for 27 years. So why not capture that energy with everyday buildings – using coatings that generate, store and release it?

This is the challenge being addressed by SPECIFIC, an Innovation and Knowledge Centre based at Swansea University. Formed in 2011 through an initial £20 million investment from EPSRC, Innovate UK and the Welsh government, SPECIFIC’s mission is to create ‘Active Buildings’ that harness all the energy a building needs from sunlight, as well as provide occupants with low-carbon energy for transport and to supply the National Grid.

SPECIFIC’s first Active Building, an off-grid demonstrator classroom, produced 1.5 times more energy than it consumed in its first year of operation. This has led to a collaboration between SPECIFIC and a social housing developer to fit 10,000 homes across South Wales with low carbon technologies.

Since 2011 SPECIFIC has received £7 million in grants from EPSRC. It has also received £40 million from its original investors and partner organisations.

SPECIFIC researchers are working on next-generation solar technologies and their manufacture and creating full-scale demonstrators to prove and test the technology. A training programme is helping to create the next generation of scientists and engineers, from basic level short courses to doctorates.

The impact of the project also goes beyond the UK. For example, partner project SUNRISE is bringing together industry and universities in the UK and India to develop off-grid low-cost solar technologies for rural Indian communities.

SPECIFIC building

SPECIFIC building